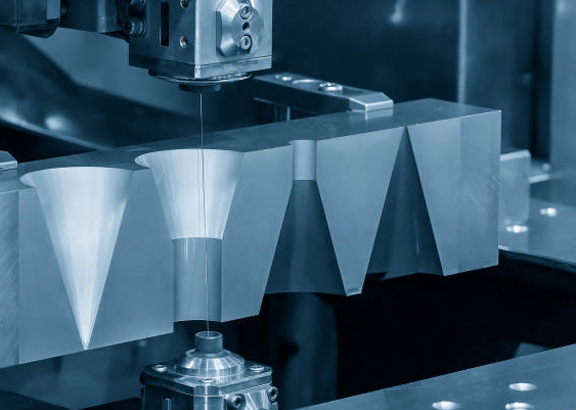

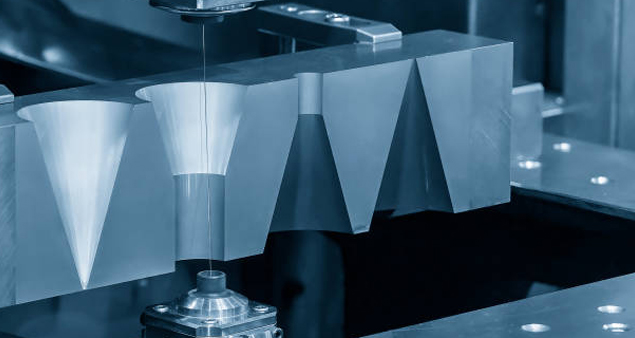

Wire EDM technologies enable the production of ultra-precise cuts through complex inner passages which makes it perfect for working on sensitive components.

Looking for precise and intricate cuts, Gree-Ge gives you advanced Wire EDM machining for complex geometries and tight tolerances. Instantly receive a quote by uploading your design today!

Gree-Ge is a leading company in Wire EDM (Electrical Discharge Machining), a method of cutting with extremely high accuracy on the workpiece without physical engagement. Our capabilities cut intricate shapes with ultra-fine detail in aluminum, steel, titanium, and exotic alloys. No matter if it’s prototype, precision components, or intricate molds, our Wire EDM solutions guarantee exceptional quality as well as superior efficiency.

In Wire EDM cutting, a thin wire is electrically charged to cut through metal parts. Extreme precision and accuracy is perfect for complex designs, sharp edges, and other features. These are impossible to achieve with traditional machining techniques. The process is used in aerospace, medical, automotive, and other industries that need precision and smooth finishes. Along with that, EDM does not involve direct tool pressure, an excellent option for wire cutting brittle or soft materials.

Check out Wire EDM parts provided by Gree-Ge. It features complex components requiring precision, intricate detailing, and ultra tight tolerances. All of our parts ensure high accuracy, burr-free and crafted for various other industries.

Gree-Ge offers plastic, metal, and alloy materials for Wire EDM Machining as well as various options for post processing to increase surface quality, durability, and functionalities.

The fastest option, leaving parts with visible tool marks and potentially sharp edges or burrs, which can be removed upon request. Surface roughness is approximately 125 µin Ra.

Media-blasted, typically with glass beads, to create a smooth, matte finish.

Type II: Provides corrosion resistance and is available in various colors, including clear, black, red, and gold. Commonly used for aluminum.

Type III: A thicker, harder layer offering enhanced wear and corrosion resistance.

A durable coating where powdered paint is applied and cured in an oven, forming a strong, wear- and corrosion-resistant finish. Available in a wide range of colors.

An electrochemical process cleans steel parts to reduce corrosion and improve appearance, by making the metal brighter. Removes about 0.0001”-0.0025” of the metal. Conforms to ASTM B912-02.

Silver offers high solderability and electrical conductivity but is susceptible to tarnish. Conforms to AMS QQ-S-365D. Thickness is about 0.00002” – 0.0003.

Gold Plating provides good corrosion and tarnish resistance with excellent solderability. Default application specification is MIL-G-45204 and ASTM B488, CLASS 00, 0, OR 1. Thickness is about 0.00002″ – 0.00005.

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

Wire Electrical Discharge Machining (Wire EDM) represents an advanced production technique which allows precise electro conductive material cutting through intricate patterns. The method of Wire EDM erodes materials through electrical discharges while preventing all touch points for both high accuracy and minimal stress buildup. The experts at Gree-Ge focus their operations on Wire EDM manufacturing to deliver detailed components which serve aerospace, medical, automotive and electronics sectors.

The operation of Wire EDM involves powering up electrical discharges between the wire and the workpiece. The sparks produce heat that vaporizes and erodes material without coming into contact with the surface. The dielectric fluid coolant functions as a cutting area protectant while removing scrap materials to maintain exact operational output.

Precise contours along with complex shapes get cut through continuous wire feeding in these machines which provide high accuracy.

High-speed cutting abilities of these machines makes them fit well in production environments that need to improve both their operational speed and product flow.

These machines employ nanosized wires for manufacturing components smaller than microscale which serve the medical field and electronics industry.

Wire EDM machines from Gree-Ge offer precise control which enables users to reach ±0.002mm tolerance levels thus enabling the production of both detailed and exact components.

Gree-Ge Wire EDM implements non-contact operations which eliminates tool pressures during the process so delicate parts stay undistorted.

The toughness of titanium and Inconel and tungsten and hardened steel does not affect precision while Wire EDM performs its cutting operation.

Wire EDM provides exact cutting while reducing material waste which leads to minimal production costs.

Wire EDM offers an effective solution for producing internal passages combined with sharp shape features and complex patterns that traditional machines cannot handle.

The aerospace industry depends heavily on Wire EDM because it delivers precision-based machining solutions that the sector requires. The process enables the production of turbine blades together with engine components, fuel nozzles and brackets. Wire EDM performs cutting operations non-thermally to maintain exact dimensions while facing high temperature and stress without experiencing part distortion.

Wire EDM operates as an indispensable tool for medical applications by creating delicate and accurate product components. Manufacturers employ Wire EDM to produce surgical instruments and orthopedic implants together with dental tools and miniature medical equipment products. Wire EDM technology enables manufacturers to cut objects free of burrs and contamination to satisfy medical industry quality criteria which uphold sanitary requirements.

Wire EDM remains essential for the automotive industry because it produces vital parts which need exact tolerances. Manufacturers need Wire EDM to produce precision gears as well as fuel injectors and transmission parts and engine components that need precise accuracy and high durability. Wire EDM produces sharp geometric shapes within tough metal components which supports extended reliable service from these parts.

Wire EDM exists as an essential instrument for tool and die-making operations. Wire EDM technology serves to manufacture precise molds even stamps, punches and extrusion dies. Wire EDM demonstrates the ability to achieve sharp corners as well as complex internal features and smooth finishes for these required tools. The manufacturing processes gain efficiency because of the high-quality tooling that Wire EDM generates.

The growing need for smaller-sized electronics components requires Wire EDM as the necessary solution for making semiconductor tools and connectors and circuit board elements and sensor parts. High precision manufacturing together with ultra-fine feature capabilities enable electronic elements to fulfill contemporary technological standards.

Defense manufacturers depend on solid parts able to remain functional under harsh operating environments. Wire EDM enables manufacturers to create firearm components as well as missile guidance system parts and exact military-grade hardware. Wire EDM processing produces parts with specific technical requirements for functioning under demanding high-stress conditions.

The Wire EDM systems at Gree-Ge install the most modern technology to deliver premium accuracy and operational efficiency.

The machine operations of Gree-Ge rely on expert machinists who specialize in Wire EDM technology to meet requirements of complex applications.

A complete inspection process and measurement routine guarantees top-level quality standards for every produced piece.

Gree-Ge minimizes waste for optimal production processes to deliver affordable pricing while maintaining product excellence.

Our company works hand in hand with clients to create Wire EDM solutions which match individual specifications.

Looking for precision cutting for complex components? Gree-Ge delivers Wire EDM solutions with unmatched accuracy. Contact us today for a consultation and quote!

Wire EDM technologies enable the production of ultra-precise cuts through complex inner passages which makes it perfect for working on sensitive components.

Wire EDM is suitable for cutting all electrically conductive materials, including stainless steel, titanium, copper, brass, and hardened tool steel.

Wire EDM operates with computer-controlled accuracy, achieving tolerances as tight as ±0.002mm, ensuring precise and repeatable results.

Our Wire EDM solutions enable both prototyping and high-volume production because they deliver exact same product quality between various pieces.

Wire EDM produces smooth finishes with minimal burrs, reducing the need for additional finishing operations.

Wire EDM minimizes material waste, reduces tool wear, and eliminates the need for extensive post-processing, making it a cost-efficient option.