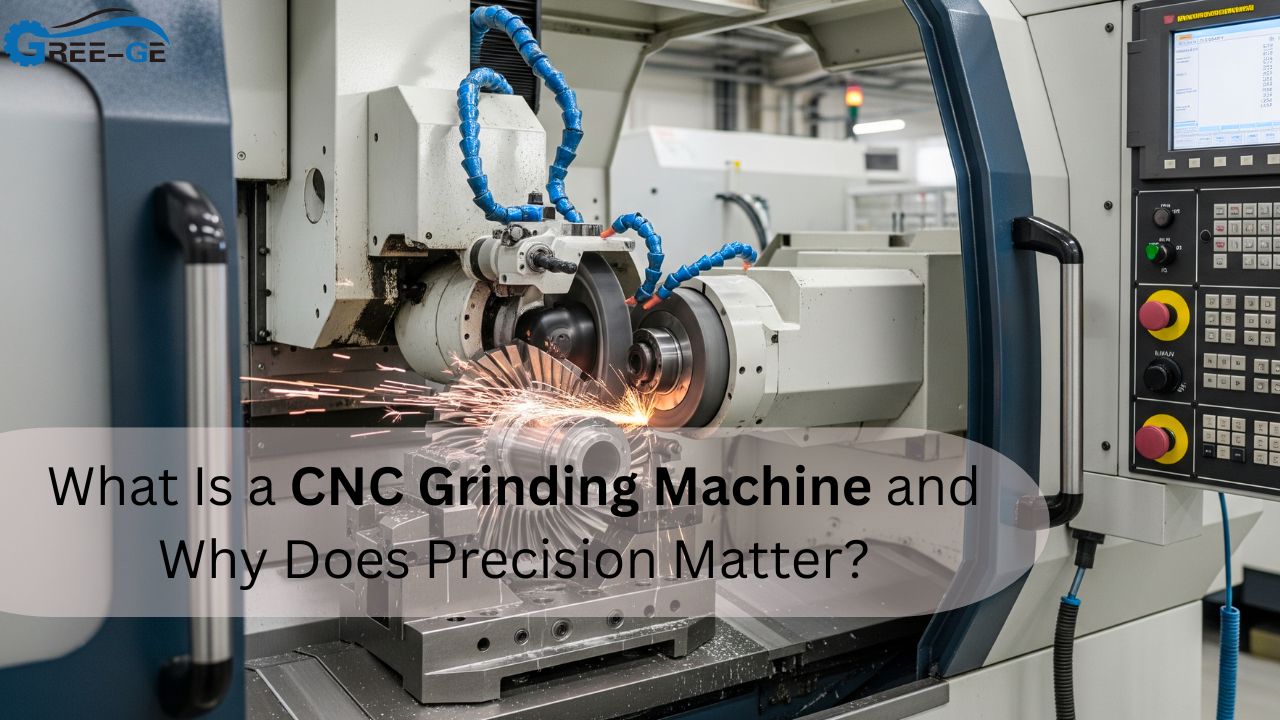

The CNC grinding machine is a sophisticated production system that offers superior accuracy, repeatability, and speed. Whether it is the aerospace industry, a car manufacturer, or a medical device engagement, these machines polish the parts down to minutely specific standards, which are the admissible limits when it comes to performance. But how do they do it, and why is such precise accuracy important?

Then what makes the CNC grinding machines so special and so indispensable in the industries that concern the precision work on the metal? We now live in the modern world of CNC machining, so we must take a closer look at the world of CNC grinders and their necessity.

How Does CNC Grinding Machine Work?

CNC grinding tools represent the automated process of material removal that is performed by rotating wheels at high speeds. These machines are able to form pieces of work to a desired shape to an extreme degree of precision, as they are controlled through a computer program.

CNC grinders are digital, unlike manual grinders, and operate using digital instructions and can give repeatable results. They find uses in small part finishing, right up to high volume CNC machining, where consistency and accuracy play major roles. They typically find use in the last stage of production to refine the surface finish, deburr, or refine close tolerances.

There are a few types of grinding machines:

- Surface grinders

- Cylindrical grinders

- Centerless grinders

- Tool and cutter grinders

All the machines are optimized to specific applications that all lead to a smooth surface and super-tight dimensional tolerance.

Why Is Grinding Crucial in CNC Machining?

People might think of the grinding process as a finishing process; however, it is a mission-critical operation in many industries. It determines the end product of precision CNC metal machining. The finest turned or milled component may need to be ground in order to have micrometer tolerances or a perfect finish.

CNC grinding often replaces complicated undercut machining and also multi-axis CNC machining, polishing away flaws and increasing durability. An example is that an aerospace and medical-grade component needs tolerance on surfaces that are on an ultra-fine level, and only a grinder can fulfill that surface tolerance.

More to the point, grinding corrects material deformation, stress relief, and thermal growth that may be present due to previous machining operations. It is a safety net to guarantee the parts are within their design blueprint.

Where Do Grinding Machines Fit in Production?

The CNC grinding machine is generally the last operation of the real-world production cycle, prior to inspection and assembly. This placement qualifies them as an essential stage to make sure that the part is both functional and aesthetically pleasing.

A typical CNC part can have several processes: milling, turning, boring, or high-volume CNC machining. The part is near complete, though not quite perfect when it arrives at the grinding stage. The role of the grinder is to provide that finishing touch.

Grinding is not optional in industries that manufacture tools, dies, and hardened parts. Without it, part performance, life, and reliability would all suffer greatly.

What Are the Benefits of CNC Grinding?

The importance of precision grinding has numerous advantages throughout the manufacturing industry. Such benefits are more than cosmetic or aesthetic and directly influence the strength, performance, and operating life of a component.

1. Unmatched Accuracy

CNC grinders produce tolerances at a level of plus or minus 0.001 mm. Such accuracy is not obtainable by hand or by common-purpose machinery.

2. Better Surface Finish

The grinding process polishes the surface, and this renders it to have low friction, an appealing look, and wear resistance. Engines or assemblies running at high speed need movement.

3. Repeatability Mass Production

In high-volume CNC machining, grinders also ensure that all pieces, the first one and the thousandth, perform to the same high-precision standard.

4. Material Flexibility

The materials to which CNC grinding is applied vary widely and include hardened steels and superalloys, ceramics, and composites, materials in which conventional cutters would quickly become worn.

5. Combining With Complicated Designs

As manufacturing designs increase in complexity, particularly grind-friendly CNC machining design tips that promote tight radii and small contours, grinding machines are necessary to realize those computer files and bring them to physical form.

How Is CNC Grinding Applied in Industry?

The flexibility of CNC grinding is the ability to cater to different industries:

- Aerospace: Turbine blade, landing gear, engine part, etc.

- Automotive: Transmission gears, camshafts, brake rotors

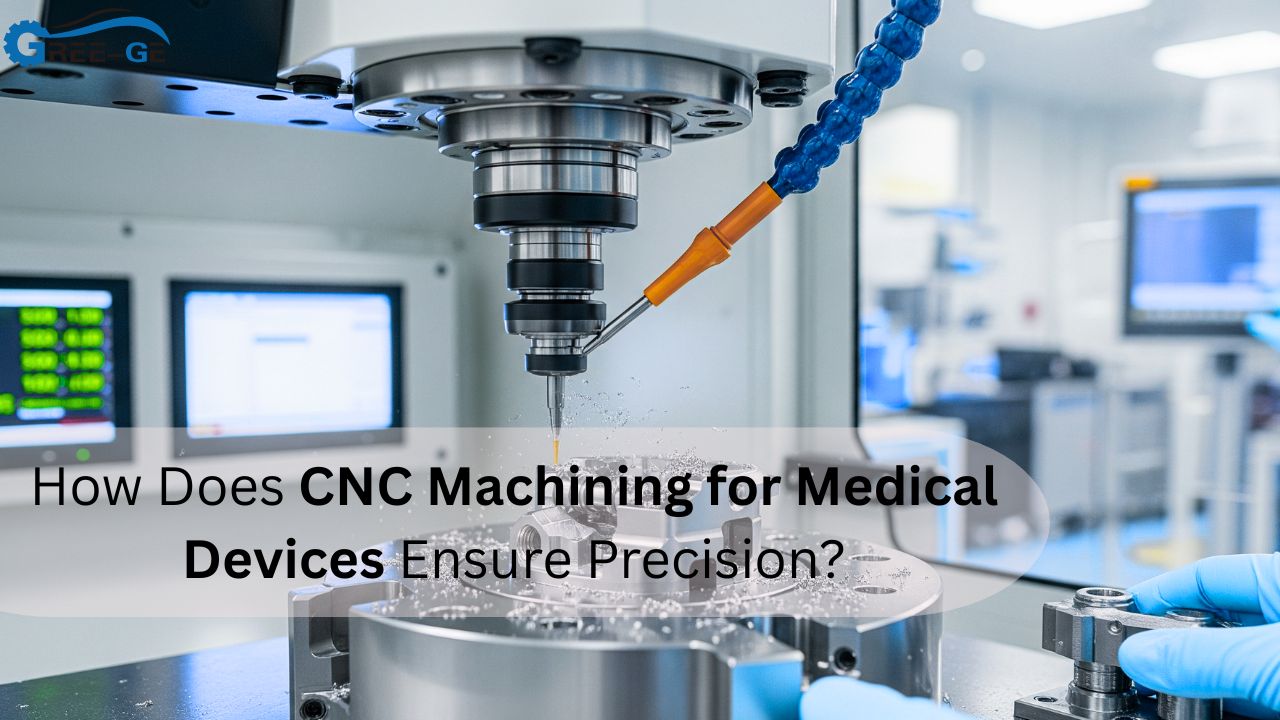

- Medical Devices: orthopedic implants, surgical instruments, dental parts

- Tool & Die: Precision molds, stamping dies, punches

In a number of such applications, the grinding stage is preceded by undercut machining or high-speed turning. The CNC grinder next brings to the party its granularity of precision, ensuring that every geometry is within tolerances to service high performance.

It can be used in precision CNC metal machining, as it is able to be integrated into the process of CAD/CAM software and automation systems, particularly where strict tolerances of less than 10 microns are needed.

Are CNC Grinding Machines Cost-Effective?

Yes, but the long-term CNC grinding machine manufacturers benefits certainly outweigh the cost. The accuracy they produce lowers the rate of part rejection and the need to finish manually and assists lean manufacturing operations.

Of greater significance, in high volume CNC machining, grinders enhance speed and cut operator malpractice, saving time and performance. They are commonly applied in lights-out production settings, which operate 24 hours a day with a minimal supervision

Manufacturers interested in sophisticated CNC machining design tips can include grinders as part of their technology to increase their capabilities without compromising on tolerances or quality standards.

A Few Things To Keep In Mind While Purchasing a CNC Grinder.

The selection of a CNC grinding machine should be based on some operational and business requirements. Some configurations are highly flexible, but others require throughput and automation. A couple of things to remember include:

- Material compatibility: will the grinder be able to handle hard alloys and special steels?

- Accuracy needs: What tolerance levels does your design require?

- Production volume: Is it for prototyping, low, or high volume CNC machining?

- Automation: Do you require in-process or integrated robots?

- Footprint and cooling: Does the shop floor have space and temperature control?

The wrong selection may restrict the efficiency of production or leave equipment underutilized, but a properly selected machine can improve ROI in a few months.

What Is the Maintenance of a CNC Grinding Machine?

Regular maintenance is crucial to get the best out of your machine’s life and performance. Now it is time to maintain your grinder:

- Coolant management: Take care of the fluids and replace them regularly so that there is no surface burn or corrosion.

- Wheel dressing: Redress wheels to retain sharpness and comprehensive accuracy of the profile.

- Lubrication: Keep the guideways, spindles, and bearings lubricated so as to avoid wear.

- Alignment: Periodically perform alignment checks in order to eliminate geometric distortions.

A preventive maintenance schedule can be used to minimize unscheduled breakdowns and ensure the accuracy of grinding during production.

Final Thoughts

Super-accurate CNC grinding machines do not simply form part and parcel of the manufacturing process; precision manufacture begins and terminates with the CNC grinding machine. In cases where components have to be capable of surviving a severe environment, grinding can reach the required accuracy, consistency, and quality guarantees required to assure that a product meets the layouts of production on a global level.

Complex undercuts, near-tolerance, and high-volume working types of production processes, and the incorporation of CNC grinding in your production process invoke reliability of the product and credibility of the customer. The technology also keeps evolving, and therefore, there is a need to have effective automated grinding solutions.

FAQs

1. What is the distinction between CNC grinding and CNC milling?

Grinding is a process that removes material through an abrasive wheel, providing a very smooth surface finish and stricter dimensional tolerances than milling, in which a rotary cutting tool removes material.

2. Is it possible to grind aluminum with CNC grinders?

Yes, aluminum is soft, but some grinding wheels and coolants are optimized for it. It can be processed by CNC grinders with fine control, without clogging or burning.

3. Can CNC grinding machines be used in undercut machining?

Absolutely. Once undercuts have been developed with multi-axis CNC tools, grinders can optimize the finish and dimensional accuracy of such cramped activities.

4. What is the accuracy of precision CNC metal machining using grinders?

Modern grinding tolerances are listed as well at 0.001 mm, rarely realized in high-performance components demanding a micrometer-precision finish, in high-performance components demanding a finish in the micrometer range.

5. Can grinding machines handle high-volume CNC machining?

Yes. CNC grinders can operate continuously with automation and multi-station fixtures and therefore are suited to large batch production settings.