Looking for precision cutting without heat distortion? Gree-Ge offers professional waterjet cutting services for a wide range of materials. Upload your design today and receive a competitive quote!

Gree-Ge provides abrasive and pure waterjet cutting, delivering high-accuracy cuts with no heat-affected zones.Our waterjet technology is ideal for metals, ceramics, glass, composites, and thick materials, ensuring clean edges and no material warping.Waterjet cutting is perfect for aerospace, automotive, architectural, and industrial applications.

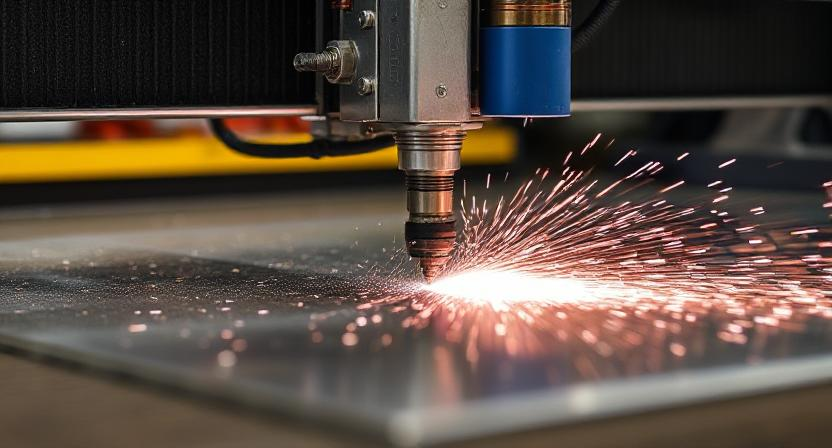

Waterjet cutting is a high-pressure cutting process that uses a stream of water mixed with abrasives to cut through tough materials with extreme accuracy. Unlike laser or plasma cutting, waterjet cutting produces no heat, ensuring no structural or chemical changes to the material. It is ideal for precision parts, intricate designs, and multi-material applications.

Explore Waterjet Cutting services by Gree-Ge, providing cold-cutting precision for thick and heat-sensitive materials with no thermal distortion.Our waterjet technology ensures smooth edges and intricate detailing for high-performance components.

| Description | General Tolerance |

|---|---|

| Distance Dimensions | For full details on tolerances offered by Gree-Ge's sheet cutting service, including edge to edge tolerance and taper, please consult our manufacturing standards. |

| Thickness Dimension | Thickness tolerances are determined by the material blank. |

| Minimum Recommend Part Size | 3.000" |

| Minimum Feature Size | 2X material thickness with a minimum of 0.125" |

| Kerf (slit size) | Approximately 0.062" |

| Edge Condition | Waterjet parts will have a vertical striation on the edges and may show a slight taper. |

Clear and Colored Acrylic (Plexiglass)

The removal of sharp edges or burrs left after the cutting process, improving the safety and smoothness of the part.

Mechanical polishing can be applied to smooth and refine the surface, creating a glossy or matte finish.

A technique used to create a uniform, textured finish. It gives a smooth but subtly textured surface

For aluminum parts, anodizing enhances corrosion resistance and can add color to the cut surface.

A durable, electrostatic coating applied to the part after cutting to provide a smooth, even finish with a range of colors and effects (from matte to gloss).

This finish is achieved by blasting fine beads onto the surface to create a uniform matte or textured appearance.

A chemical treatment that vapor smooths the surface of parts made from materials like plastic by removing visible imperfections.

Laser engraving or etching can be used to add designs, logos, or text on the surface after the water jet cutting process, offering detailed and precise markings.

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!