CNC (Computer Numerical Control) technology, a key player in the world of manufacturing, has significantly transformed modern production processes. In the broader concept of turning in machining, a standout application known as CNC turning takes center stage. In this blog, we delve deep into this subject, highlighting the advantages, uses, and future potential of CNC turning applications. As we journey through this topic, we will also spotlight the critical roles of CNC turning service suppliers and CNC turning factories in various industries.

What is CNC Turning Applications?

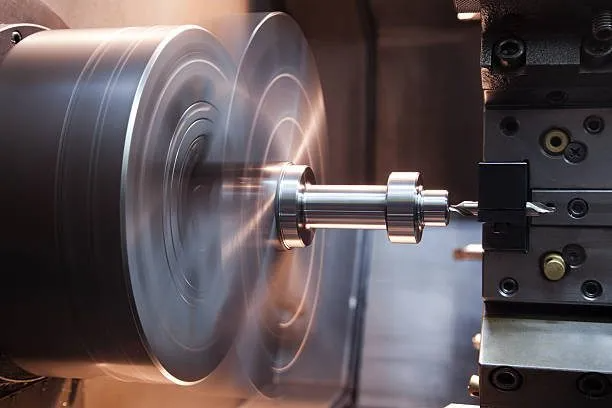

Turning in machining involves a specific process where a cutting tool, typically a non-rotary tool bit, describes a helical toolpath by moving more or less linearly while the workpiece rotates. Among the myriad applications of turning in machining, CNC turning applications is notably prominent. Here, a piece of raw material rotates while a cutting tool shapes it, resulting in a cylindrical part with precise dimensions. The computer-controlled machine, loaded with pre-programmed software, governs the movements of the tools, offering an accuracy level that eclipses what traditional manual lathes could achieve.

The Role of CNC Turning Service Suppliers and CNC Turning Factories

CNC turning service suppliers and CNC turning factories play a critical role in delivering precision, efficiency, and versatility, the primary advantages of CNC turning in machining.

CNC turning service suppliers offer expert services to businesses across industries. These suppliers have the knowledge and experience to meet specific requirements and deliver components that adhere to precise specifications and high-quality standards. They often provide a complete range of services, from prototype creation to full-scale production.

CNC turning factories, on the other hand, are the powerhouses where the actual production happens. These factories house advanced CNC turning applications and expert technicians who run them. The factories stand as a testament to modern technological advancements, churning out high-quality, precisely machined components with impressive efficiency.

Advantages of CNC Turning in Machining

CNC turning, a fundamental process of turning in machining, offers numerous advantages, especially when facilitated by reputable CNC machining service suppliers and executed in a well-equipped CNC turning factory.

Precision

Precision is paramount in industries where even the slightest error can have substantial repercussions. The high accuracy offered by turning in machining, particularly when carried out in a CNC turning factory and orchestrated by experienced CNC turning service suppliers, is one of its primary strengths.

Efficiency

Turning in machining, especially CNC turning, allows for uninterrupted production with minimal human intervention, thanks to the automated processes employed by CNC turning applications suppliers and implemented in CNC turning machine.

Versatility

As an application of turning in machining, CNC turning is versatile, capable of producing a broad array of products from various materials, ranging from simple rings to complex components with intricate designs.

Application Areas of CNC Turning

CNC turning service suppliers and CNC turning factories cater to a broad spectrum of industries, providing them with critical components necessary for their operations.

Automotive Industry

The automotive sector heavily relies on turning in machining, specifically CNC turning, for the production of many critical parts.

Aerospace Industry

Turning in machining, and in particular CNC turning, plays a crucial role in the aerospace sector, where precision and reliability are critical.

Medical Industry

The medical industry employs CNC turning applications in creating precise, high-quality parts such as surgical tools, implants, and equipment components.

The Future of CNC Turning in Machining

As technology continues to evolve, we can anticipate turning in machining, and more specifically, CNC turning, to further develop. The roles of CNC turning service suppliers and CNC turning factories will likely become even more critical, adapting to new advancements and requirements in various industries.

In conclusion, CNC turning has proven itself to be a vital process in modern manufacturing, offering an unmatched blend of precision, efficiency, and versatility. As we look forward to the future of turning in machining, the continuous growth of CNC turning applications suppliers and CNC turning factories will undoubtedly play a significant role in shaping this exciting landscape.