An efficient method is making a sheet metal prototype to put an idea into the picture. It helps test the design before full-scale production and is applied in industries such as automotive, aerospace, and consumer electronics. Its advantages are that it is durable, has high turnaround, and precision. One of the methods that businesses employ in order to cut expenses and enhance quality of products earlier in the process.

What is a Sheet Metal Prototype?

A sheet metal prototype is a sample part made from thin sheets of metal. It is often used to check the design, shape, and strength of a product. Engineers and designers use it to test fit and function. It saves money by fixing design flaws early. This also speeds up the development process. Sheet metal is shaped using different processes like cutting, bending, and welding. Prototype phase helps verify if the design meets project goals.

Sheet metal prototypes are not just samples. They are tools for learning and improving. Help detect problems before the actual product is made. These prototypes are strong and cost-effective. They are made with processes like sheet metal fabrication and CNC metal cutting machines. You can test their performance in real-world conditions. This gives confidence in the final product. A good prototype reduces production delays.

Sheet Metal Fabrication Methods

Sheet metal fabrication involves turning flat metal sheets into final products. They allow for clean, precise cuts. Here’s a look at the most common methods used:

Common Sheet Metal Fabrication Methods

| Method | Description | Best For |

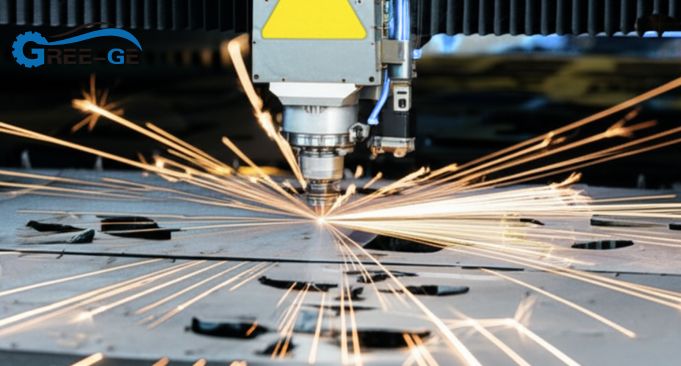

| Laser Cutting | Uses laser beam to cut precise shapes | Complex shapes and fast cuts |

| Bending | Metal is bent into angles or curves | Enclosures, brackets |

| Punching | Punches holes or shapes using press machines | Vents, slots |

| Welding | Joins two metal parts together | Structural strength |

| Deburring | Removes sharp edges after cutting | Smooth and safe finishes |

Each method supports a part of the prototype creation. Together, they help bring the product to life. These processes can be repeated with accuracy in large-scale production.

Tools and Equipment Used

To build a sheet metal prototype, specific machines are required. Some tools are standard, and others are high-tech. CNC machines play a major role in producing accurate metal parts. These machines cut metal using digital instructions.

Precision CNC metal machining adds detail to metal parts. It offers smooth surfaces and accurate dimensions. Advanced machines can perform multiple tasks, including drilling, cutting, and engraving.”

Tools Used in Sheet Metal Prototyping

| Tool/Machine | Purpose | Key Feature |

| CNC Laser Cutter | Cuts detailed shapes into sheet metal | High accuracy and clean edges |

| CNC Punching Machine | Makes holes and slots | Fast and repeatable |

| Press Brake | Bends metal into required angles | Precise bending at custom angles |

| MIG/TIG Welder | Joins metal pieces | Strong and durable joints |

| Sheet Metal Shear | Straight cutting of metal sheets | Ideal for quick straight cuts |

Using the right tool ensures a high-quality prototype. CNC machining Services tools are especially good for fast and precise production. They allow testing even the most detailed designs.

Advantages of Using Sheet Metal Prototypes

There are many benefits to using a sheet metal prototype in product development. First, it gives you a physical model to test. You can check the size, shape, and functionality. This helps avoid expensive mistakes later.

Second, the prototypes are durable. They can handle pressure and temperature tests. Third, they reduce design and production time. You can quickly move from design to final product. Also, the use of sheet cutting and CNC machines lowers labor costs.

Some more key benefits are:

- Fast turnaround times

- Improved product accuracy

- Lower testing costs

- Real-world product validation

- Easy to modify for future versions

These advantages make metal prototypes a smart choice for manufacturers. They help create better products at lower costs.

Industries That Use Sheet Metal Prototypes

Many industries rely on sheet metal fabrication and prototypes to design quality parts. From large factories to small startups, these services are in high demand. Here are some industries where metal prototypes are widely used:

- Automotive: For body panels, engine parts, and brackets

- Aerospace: Used in structural components and housings

- Electronics: Cases, enclosures, and frames

- Medical Devices: Equipment covers and support structures

- Home Appliances: Oven panels, refrigerator parts

In these industries, there is a demand for strong, lightweight, and custom-made metal components. Prototypes assist in checking the size, and how they operate prior to full production.

Sheet Cutting and CNC Technology

Sheet cutting is the process of slicing metal sheets into specific shapes. The goal is to get accurate cuts with minimal waste. Laser cutting is most used for its speed and precision.

CNC metal cutting machines improve this process even more. CNC stands for Computer Numerical Control. These machines use coded instructions to guide cutting tools. They reduce errors and work at high speed. CNC technology ensures repeatable quality.

Tips for Creating the Best Sheet Metal Prototype

- Use accurate CAD designs – Start with detailed computer models.

- Choose the right metal – Consider strength, weight, and cost.

- Select the best fabrication method – Match the process with the design.

- Work with experienced machinists – Experts can avoid costly errors.

- Test early and often – Use the prototype to make quick improvements.

These tips ensure you get the most out of your prototype. A well-made prototype leads to a better final product.

Final Thoughts

The process of producing a sheet metal prototype is an intelligent idea to make your ideas become real. It assists to detect any design problems in an early stage and fastens the manufacturing process. By means of sheet metal fabrication, sheet cutting, and an accurate set of CNC metal machining. Companies are enabled to test and introduce an improved product. Using CNC tools and the right fabrication methods gives accurate and strong parts.

FAQs

What is a sheet metal prototype?

A sheet metal prototype is a sample metal part used to test design, shape, and fit before full production.

Which industries use sheet metal prototypes?

Metal prototypes are quickly and effectively used in testing and production of parts in industries such as automotive, electronics and medical devices.

Which are the machines involved in prototyping of sheet metal?

CNC laser cutters, punching machines, press brakes. Additionally, welders are frequently employed to produce accurate and long-lasting prototypes.

How accurate are CNC metal cutting machines?

CNC machines offer high precision with minimal errors. They follow digital instructions for consistent and repeatable results.

Why is sheet cutting important in prototyping?

Sheet cutting shapes the metal into exact designs. It ensures parts are made correctly and reduces material waste.