Looking for precise and efficient sheet cutting solutions? Gree-Ge offers high-quality sheet cutting services for a wide range of materials and applications.Upload your design today and receive a competitive quote!

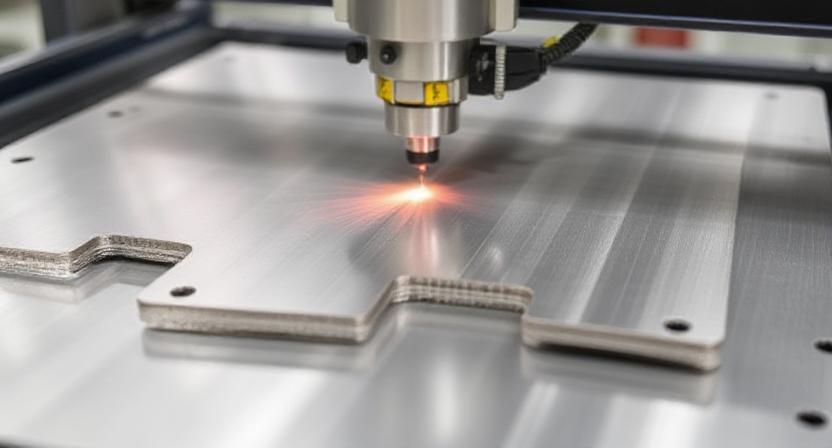

Gree-Ge provides advanced sheet cutting services,ensuring high precision,clean edges,and minimal material waste.Whether you need metal,plastic,or composite sheets cut to exact specifications,our cutting technology guarantees tight tolerances and smooth finishes.We specialize in custom sheet fabrication for automotive,aerospace,industrial,and consumer applications,offering fast turnaround times and cost-effective production.

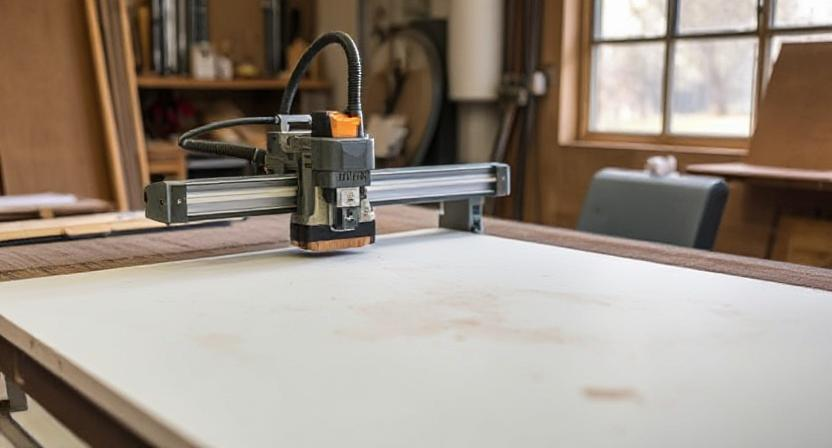

Sheet cutting is a manufacturing process used to cut flat materials into specific shapes and sizes using techniques like laser cutting, waterjet cutting, and CNC shearing. This process allows for high-accuracy part production with minimal material distortion, making it ideal for custom enclosures, panels, brackets and industrial components.

Explore precision Sheet Cutting services by Gree-Ge,offering high-accuracy cuts for various materials,including metals,plastics,and composites.Our advanced cutting techniques ensure clean edges,tight tolerances,and minimal material waste for diverse applications.

| Feature | Description |

|---|---|

| Blank Size | Gree-Ge has access to platforms up to 10’ x 20’ for laser cutting and waterjet cutting. However, many sheet stock sizes commonly cap out at 48” x 96” (4’ x 8’) or smaller. |

| Standard Lead Time | 3 business days |

| Sheet Thickness | 0.020" up to beyond 1.00" depending on materials. Thinner or thicker stock may be possible through manual quoting. |

| General Tolerances | For full details on tolerances offered by Gree-Ge's sheet cutting service, including edge to edge tolerance and taper, please consult our manufacturing standards. |

Clear and Colored Acrylic (Plexiglass)

Parts are finished in a blasting cabinet where a high-pressure stream of fine glass beads (typically 80-grit) is applied at pressures between 70-100 psi.

Parts are processed in a vibratory or rotary tumbler with abrasive tumbling media. This results in an even stippled finish across the part’s surface and helps to round sharp edges and corners.

A standard finish is provided for all materials with no additional post-processing. The part’s surface remains in its natural state after de-tabbing and deburring.

Metal parts are hand-sanded, or sanded using an abrasive belt sander or timesaver, following the direction of the grain to achieve a consistent finish.

Metal parts are sanded by hand, orbital sander, or timesaver in a random, swirling motion to create a uniform finish. .

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!