Looking for durable and high-performance 3D-printed parts? Gree-Ge has you covered with Selective Laser Sintering (SLS) services, which are perfect for functional prototypes and intricate designs. Upload your design now to get a competitive quote!

At Gree-Ge, we know SLS 3D printing very well, a powder based method of construction that results in strong, lightweight, and well detailed structures or parts without the necessity of additional support. We are specialized for creating parts for the aerospace, automotive, medical, and consumer goods industries. We prefer the highest quality materials such as Nylon, PA12, PA11, and flexible TPU. In addition, SLS works very well for functional prototypes, production parts, and complex assemblies, providing excellent mechanical properties, temperature resistance as well as chemical durability.

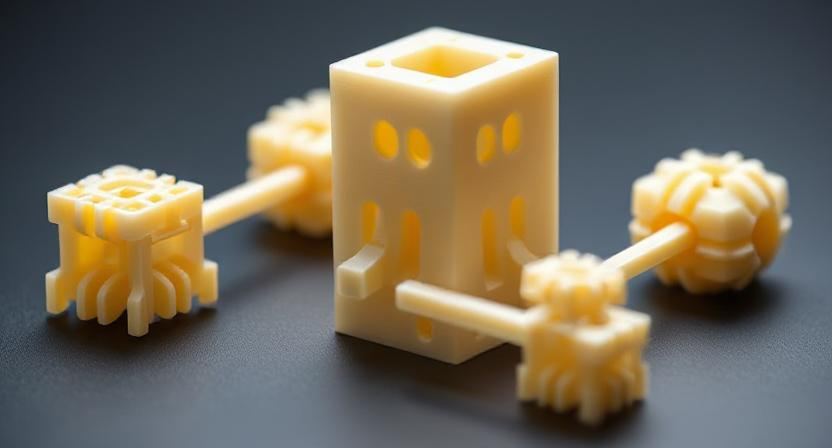

SLS is a modern construction approach that applies a laser beam to thermoplastic powder to fuse layers to make robust components. One of the many advantages of SLS is, no support frameworks are needed. Complex and intricate pieces can be constructed with great precision. Making it ideal for engineering custom parts and lightweight structures that need to resist real world conditions.

SLS 3D printed parts by Gree-Ge are made of high-strength materials with complex geometries and no supporting structures which guarantee freedom of design. Our SLS technology provides durable, heat resistant, and functional parts for tough applications.

| Description | Tolerance Notes |

|---|---|

| General Tolerances | SLS Nylon 12 and variants are ± 0.015”, or ± 0.002" per inch, whichever is greater.* SLS Nylon 11 and variants are ± 0.020”, or ± 0.003" per inch, whichever is greater.* *Results are typical. |

| Build Area | Build area up to 13" x 13" x 20". Glass filled can extend up to 26" x 15" x 23". |

| Minimum Feature Size | 0.030" or greater. |

| Standard Layer Thickness | 0.12 mm / .0047" |

Durable plastic

Stiff plastic

Ductile plastic

High-performance plastic

De-powdered via sandblasting and manual removal, with internal holes drilled if accessible. Finish is white matte (fine sugar-cube texture).

Uses fine beads of material like glass or ceramic to blast the surface, creating a smooth, matte finish. It helps remove any excess powder from the surface and creates a uniform texture.

Automated process (AMT PostPro3D) that transitions surfaces from matte to semi-gloss, seals surfaces, enhances mechanical properties, and offers a consistent cosmetic finish. Can be dyed.

Abrasive tumbling softens edges and reduces growth lines, leaving an eggshell finish.

Copper + nickel plating adds 0.004″-0.006″ coating for enhanced durability, stiffness, and wear resistance, with a rough nickel finish.

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!