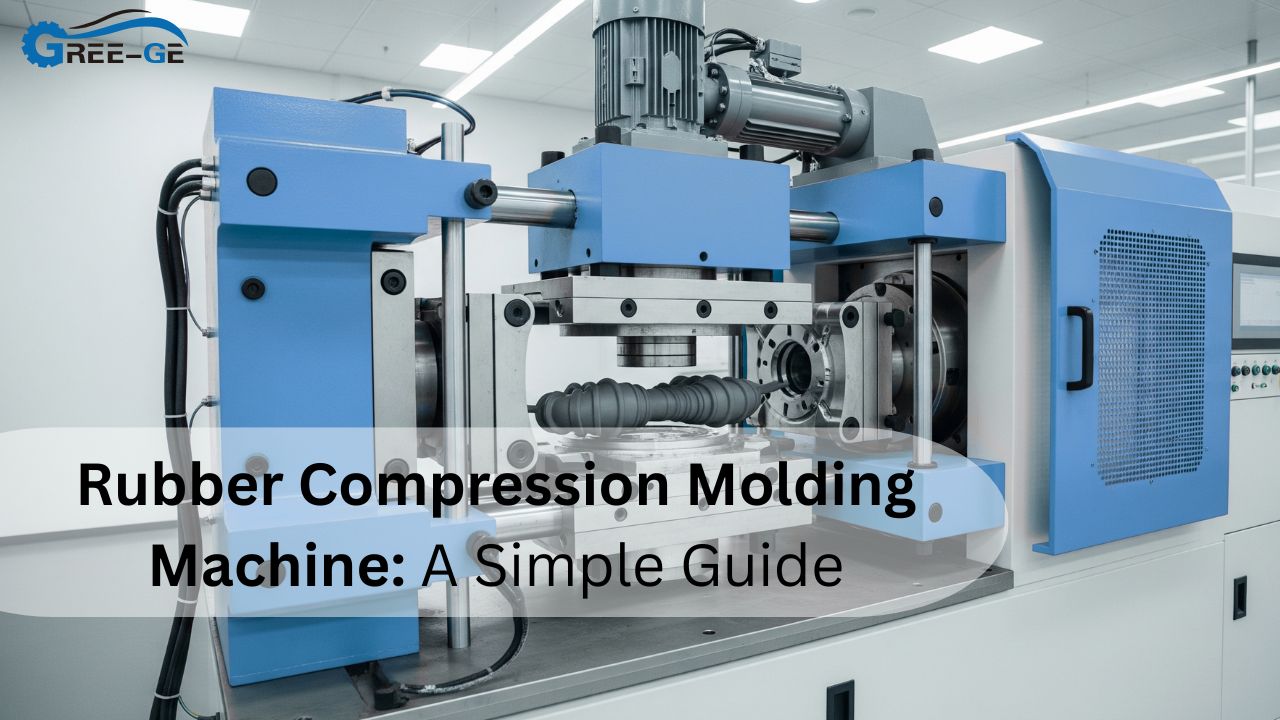

Rubber compression molding machine is an essential machine used to mold the rubber. This involves the use of a machine that applies heat and pressure to convert rubber into the desired shape. It is an easy and economical process — and perfect for various industries. This is often used to make seals, gaskets, and rubber automotive parts. This technique has existed for ages. It works by placing rubber into a heated mold. Then, the mold closes and applies pressure. After a set time, the mold opens, and the shaped rubber is removed. This process is known for its strength and precision.

How Does a Rubber Compression Molding Machine Work?

The machine has a top and bottom plate. These plates are heated. Rubber is placed in the cavity of the mold. The mold is closed with high pressure. Heat and pressure form the rubber into the desired shape. Once the cycle ends, the mold opens. The finished part is taken out. This process can take several minutes depending on the part size. The machine repeats the process with new material each time.

Benefits of Rubber Compression Molding Machines

This rubber compression molding machine process is ideal for small to medium production molding runs. It is simple and doesn’t need complex machinery. Let’s explore some of the main advantages:

- Lower Cost: Compared to other methods, it’s less expensive.

- Simple Design: Fewer parts mean less maintenance.

- Durable Output: The parts are strong and long-lasting.

- Flexible Materials: Works well with natural and synthetic rubber.

Compression molding also creates less waste. It’s suitable for thick or bulky parts. This makes it popular in industries like automotive and healthcare.

Comparison with Other Molding Techniques

Let’s compare rubber compression molding machines with other common molding methods. This will help you understand when to choose it over others.

Comparison of Molding Methods

| Feature | Compression Molding | Plastic Injection Molding | Prototype Injection Molding |

| Material Type | Rubber | Thermoplastics | Thermoplastics |

| Setup Cost | Low | Medium to High | Low to Medium |

| Tooling Complexity | Simple | Complex | Simple to Moderate |

| Best Use Case | Large, thick rubber parts | Mass plastic production | Early-stage product development |

| Cycle Time | Long (3-10 minutes) | Short (seconds) | Varies (fast for prototypes) |

| Waste Generation | Low | Moderate | Moderate |

As seen above, rubber compression molding machines are best for producing strong, thick rubber components. If you’re dealing with early testing, prototype injection molding may be better. For plastic items, plastic injection molding is the top choice.

Applications of Rubber Compression Molding Machines

These machines are used in various sectors. They serve industries that need precision and durability. Here are a few major uses:

- Automotive: For seals, bushings, and gaskets.

- Medical: Creating safe and durable rubber parts.

- Industrial: Making parts for heavy machinery.

- Consumer Goods: In products like footwear or kitchen tools.

Because the method handles high pressure and heat, it makes tough parts. These parts resist wear, heat, and chemicals. That’s why many manufacturers rely on it.

Main Parts of a Rubber Compression Molding Machine

Each machine has key parts that play a role in the process. These parts work together to shape rubber into perfect forms.

Components of the Machine

| Part Name | Function Description |

| Heating Plates | Provide heat to cure the rubber |

| Mold Cavity | The shape where rubber is placed |

| Press Mechanism | Applies pressure to mold the rubber |

| Control Panel | Manages time, temperature, and pressure settings |

| Safety Guard | Protects the operator during machine operation |

| Hydraulic System | Drives the press mechanism with high force |

These components ensure quality results every time. A well-maintained machine can last many years. Regular checks improve the output and reduce downtime.

Differences Between Rubber and Plastic Molding

Rubber molding and plastic injection molding look similar but are quite different. Rubber needs more pressure and heat. It also cures instead of just melting. Plastic molding involves injecting melted plastic quickly into a mold. Rubber molding is slower but more durable. It is best for flexible, heat-resistant parts. Plastic molding is great for lightweight, rigid components in large numbers.

Tooling in Rubber Compression Molding

Tooling is important in every molding process. In rubber compression molding, the mold is simpler. It doesn’t need complex injection systems. This lowers the cost. But it still takes some talent to design the mold. It also needs to match with the rubber shape, size and momentum. Injection mold tooling helps in the life of the product. So for a prototype injection molding tool, soft metal is fine. This helps to reduce the expenditure and increase production time.

Choosing the Right Molding Method

To decide which process suits you best, ask a few key questions:

- What material will you use? If rubber, go for compression molding.

- How many parts do you need? For mass production, consider injection molding.

- Is cost a major factor? Compression molding is more budget-friendly.

- Are you making a prototype? Use prototype molding for testing.

When these answers are clear, you can pick the right path. Each method has strengths depending on the need.

Modern Trends in Molding Machines

Today’s rubber compression molding machines are becoming smarter. Many now have digital controls. These let you set exact pressure and heat levels. Some even have automated loading and unloading features. Also, energy-saving designs are common. They help lower operating costs. Many manufacturers look for machines with quick changeover times. This saves time when switching between molds.

Maintenance Tips

To keep your machine working well:

- Check heating plates regularly.

- Clean molds after each use.

- Monitor hydraulic systems.

- Lubricate moving parts.

- Replace worn-out components quickly.

These steps help avoid production delays. A small issue can cause big problems later.

Final Thoughts

A rubber compression molding machine is a crucial thing that helps to shape the products you want according to your wish. It is accurate, inexpensive, and adaptable. This is a powerful machine that caters to automotive and industrial components with an ability to deliver well. This is great for small to mid level production. It’s easy to set up and use. Be sure to know what type of material you need, your budget and quantity needs if you are deciding between molding options. When it comes to plastic injection molding or early prototype injection molding — knowing your choices can give you the edge.

FAQs

What is a rubber compression molding machine used for?

It shapes rubber parts using heat and pressure.

How is it different from plastic injection molding?

It uses rubber and cures slowly, while plastic injection uses melted plastic and is faster.

Is it good for small production runs?

Yes, it is cost-effective and ideal for low to mid-volume production.

What industries use rubber compression molding machines?

They are used in automotive, medical, industrial, and consumer product manufacturing.

How long does one molding cycle take?

A typical cycle takes between 3 to 10 minutes, depending on part size and material.