Gree-Ge offers rapid prototyping with turnaround times ranging from a few days to a couple of weeks, depending on the complexity of the design.

Looking to test your product design with real molded parts? Gree-Ge offers high-quality Prototype Molding services to bring your designs to life quickly. Upload your design today and receive an instant quote!

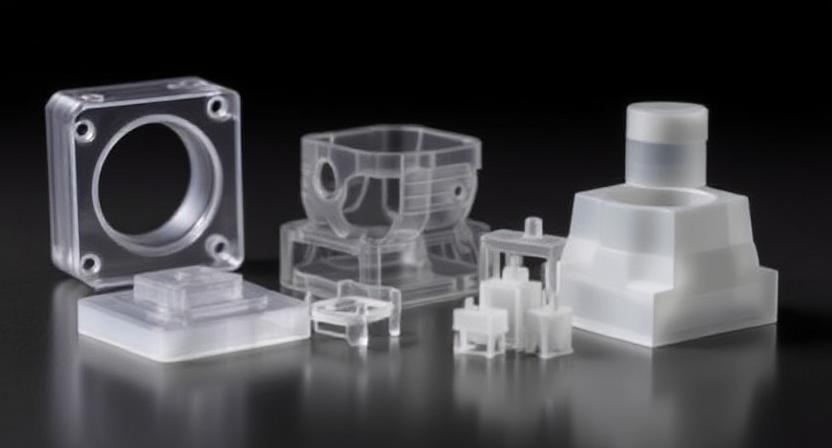

Gree-Ge specializes in prototype injection molding, providing functional and durable prototypes to validate designs before mass production. Our services ensure accurate, high-performance parts made from production-grade materials, giving you the ability to test designs under real-world conditions. Whether for functional prototypes or design validation, we deliver fast turnaround times and cost-effective solutions.

Prototype Molding is a process that uses injection molding to create a small batch of parts to test design concepts before full-scale production. This process enables rapid prototyping of functional parts, ensuring accurate geometry and material properties to test fit, form, and function in real-world conditions.

Explore Prototype Molding services by Gree-Ge, offering high-precision molds for rapid development of functional prototypes. Our prototype molding services help bring your designs to life quickly, allowing for design validation and testing before mass production.

Our Prototype molding materials offer a wide range of options, are certified, and environmentally friendly, providing premium solutions for your products. Contact us now to learn more!

Removes sharp edges or burrs formed during the molding process to ensure smoothness and safety.

Enhances the appearance of the part by using abrasive materials to achieve a smooth, glossy finish.

Textured finishes are commonly used for prototypes to test how certain patterns or surfaces will look or feel.

Creates a uniform matte or satin finish by bead blasting the part with fine abrasive media, improving texture and removing surface imperfections.

This is often used to smooth prototype parts, especially when the design requires uniformity or removing flash.

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

Prototype Molding creates operational prototypes specifically for pre-production testing. Through its production process, businesses test new products’ designs while examining performance and implementing required modifications so they can minimize product risks together with manufacturing expenses.

Gree-Ge enables businesses to access high-quality prototype molding services which efficiently develop their products.

Prototype Molding consists of a specific workflow which enables efficient manufacturing of test parts without errors:

The first step includes creating computer-aided design (CAD) models for developing the prototype mold through 3D modeling. A detailed analysis of the design occurs to make sure the part can be manufactured successfully and the geometry needs improvement for the injection molding process.

Plastics suitable for a specific application are selected according to their strength capacity along with durability features and temperature tolerance together with usage constraints.

The creation of prototype molds occurs through CNC machining or 3D printing under the process known as rapid tooling. The mold production timeline becomes faster through using high-speed machining alongside low-volume tooling methods.

High pressure completes the injection of molten plastic into the mold cavity. The implementation of advanced cooling systems improves production rate while ensuring all parts develop uniformly.

Testing of the prototype includes multiple post-processing stages that include cuts and finish work and functionality checks for design requirements verification.

Before proceeding to full production, engineers perform testing analysis which leads to required modifications to the mold and part design. Development teams can easily apply test variants to optimize performance output.

Industrial risks during manufacturing are diminished through the process which detects part fit issues together with function and assembly problems before big production starts.

Fast yet efficient CNC machining, 3D printing together with high-precision molding enable us to produce high-quality prototypes in a short period.

Gree-Ge provides different plastic injection molding products such as ABS and polycarbonate and nylon and PEEK which match specific application needs.

Our fast prototype manufacturing method shortens project timelines thus it helps businesses speed up their product development cycle.

All prototypes undergo thorough inspection procedures together with functional testing for verifying superior accuracy and durability standards.

The precision manufacturing industry employs Prototype Molding as a standard technical process within fields such as automotive manufacturing and medical sector along with consumer product testing.

Contact Gree-Ge today to get started with Prototype Molding and bring your product ideas to life!

How long does it take to produce a prototype?

Gree-Ge offers rapid prototyping with turnaround times ranging from a few days to a couple of weeks, depending on the complexity of the design.

Is Prototype Molding cost-effective?

Yes, it reduces costs by identifying design flaws early, preventing expensive modifications during full-scale production.

Can Prototype Molding be used for functional testing?

Absolutely. Our prototypes are designed to simulate real-world conditions and performance requirements before mass production.

What industries benefit from Prototype Molding?

Industries such as automotive, medical, aerospace, consumer products, and electronics benefit from prototype molding to accelerate product development.

Why should I choose Gree-Ge for Prototype Molding?

Gree-Ge offers precision, speed, and expert support, ensuring high-quality prototypes that streamline the transition from design to full production.