There are numerous industries in which Precision Sheet Metal Fabrication takes a significant value. It is utilized in the manufacturing of quality parts in the automotive, aerospace and many more. The whole thing involves slicing, forming and joining metal sheets down to the finest degree of precision. It makes sure that all components are on a tight specification. This is the reason that makes it very useful in engineering and manufacturing sectors. In this blog, you’ll learn what precision sheet metal fabrication means. We’ll also explore its techniques, tools, and benefits.

What Is Precision Sheet Metal Fabrication?

Precision sheet metal fabrication is a kind of process that includes shaping and cutting of thin metal sheets. They aim at producing pieces according to precise designs. When it comes to accuracy, it is quite important because little mistakes during the process might lead to tremendous problems. This may involve cutting of sheets, bending, punching, welding and forming. Tools like CNC machining make this possible.

Why Is It Important?

Precision matters in industries like aerospace, medical devices, and electronics. These fields need parts that fit perfectly. Even the smallest difference in shape or size can cause a failure. By using precision sheet metal fabrication, companies save time and reduce waste. It leads to faster production and better quality. Also, these parts often don’t need extra finishing, saving cost.

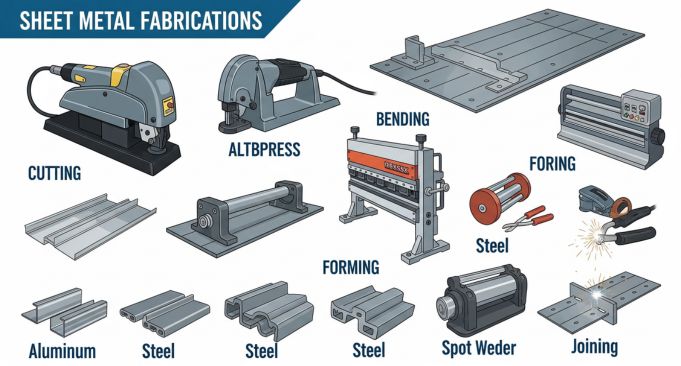

Key Techniques in Sheet Metal Fabrication

Many methods are used in this process. Some of the most common ones are:

Laser Cutting

It uses a focused laser beam to cut metal sheets. This offers clean edges and accurate shapes.

Punching

Punching machines make holes or shapes in the metal. It’s fast and works well for repeat jobs.

Bending

The machine folds the metal at specific angles.

Welding

Welding joins two or more parts. In sheet metal work, it needs to be clean and precise.

Common Materials Used

In precision sheet metal fabrication, materials are chosen based on strength and purpose. Here are some common ones:

- Aluminum: Lightweight and corrosion-resistant

- Stainless Steel: Durable and rust-proof

- Mild Steel: Affordable and easy to cut

- Copper: Good for electrical applications

These materials are shaped into sheet metal prototypes or final parts using CNC tools.

Sheet Metal Prototype Development

A sheet metal prototype is a sample made before mass production. It helps to test the design and make sure everything fits. This step is important in reducing mistakes. Making a prototype also lets engineers see how the part will look and perform. It’s often made using the same machines as final parts. So, CNC tools and laser cutters are used here too.

Tools Used in Precision Sheet Metal Fabrication

| Tool Name | Purpose | Common Use |

| CNC Metal Cutting Machines | Automated cutting with accuracy | Used for large-scale projects |

| Laser Cutter | Precise, clean cuts | Complex shapes & fine edges |

| Press Brake | Bending and folding | Making angles and folds |

| Punch Press | Hole punching | Quick repetitive shapes |

| Welding Machine | Joining parts | Final assembly |

CNC Metal Cutting Machines

These machines are essential in this process. CNC stands for “Computer Numerical Control.” That means a computer guides the machine. This leads to very accurate cuts and shapes. These machines can cut, punch, and drill with high speed and low error. They’re perfect for both large and small runs. The use of CNC metal cutting machines also ensures safety and efficiency.

Benefits of Precision Sheet Metal Fabrication

Here are some strong reasons to use this method:

High Accuracy

Parts are made with exact measurements.

Low Waste

Machines reduce errors and save material.

Fast Production

Automated tools finish jobs quickly.

Cost Efficiency

Less waste and faster work mean lower costs.

Scalability

Great for small runs and large batches.

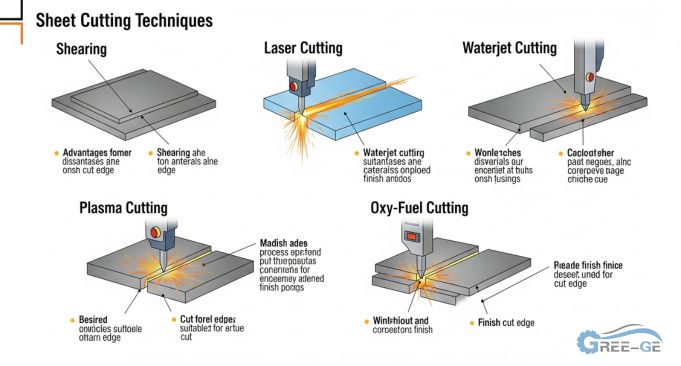

Sheet Cutting Techniques

Sheet cutting is the first step in many projects. It involves trimming the metal into the needed size or shape. It’s can be done in several ways:

Shearing

Uses a straight blade to slice the sheet.

Plasma Cutting

Uses high-heat gas to cut thick metal.

Water Jet Cutting

A high-pressure stream of water jet cutting and abrasive material cuts the sheet.

Each technique has its pros and cons. Your choice depends on the material and job.

Comparison of Sheet Cutting Methods

| Method | Best For | Advantages | Limitations |

| Laser Cutting | Thin metal, fine shapes | Very precise, low waste | Not ideal for thick metals |

| Plasma Cutting | Thick metals | Fast and strong | Less precise than lasers |

| Water Jet Cutting | Heat-sensitive jobs | No heat damage, clean cuts | Slower and more expensive |

| Shearing | Simple straight cuts | Fast and affordable | Can’t cut curves or angles |

Industries That Use Precision Sheet Metal Fabrication

This process is used in many industries:

- Automotive: For body parts and components

- Aerospace: For engine parts and control panels

- Medical: For surgical tools and machines

- Telecom: For signal boxes and racks

- Construction: For roofing and frames

Each industry relies on high accuracy and long-lasting parts. That’s where precision sheet metal fabrication proves valuable.

The Role of Design Software

Before cutting or forming begins, design software is used. Programs like AutoCAD or SolidWorks are common. They let engineers create detailed plans. These plans guide the machines during fabrication. Using design software reduces errors and ensures every part matches the drawing. This is important in sheet metal prototype development.

Future Trends

The future of this field looks promising. More companies are using CNC metal cutting machines. Automation and robotics are improving speed and reducing human error. Smart sensors now monitor the machines. These sensors make sure each part meets the standards.

Conclusion

Precision Sheet Metal Fabrication plays an important role in the modern industries. It is a speedy and low-cost method to produce superior parts. This process is accurate whether you are trying to establish a sheet metal prototype or doing an entire production run. The process continues to get better with the usage of strong tools such as CNC metal cutting machines or a stronger software.

FAQs

What is precision sheet metal fabrication?

It involves shaping and cutting metal sheets to precise detail in the industrial applications.

Which kinds of machines are applied in sheet metal work?

The well-known ones include CNC machines, laser cutters, press brakes and the welding machines.

Why are prototypes important in sheet metal fabrication?

They help test the design before mass production and reduce costly errors.

Which materials are best for precision fabrication?

Aluminum, stainless steel, and mild steel are popular due to their strength and flexibility.

Is CNC better than manual cutting?

Yes, CNC machines offer more accuracy, speed, and safety.