You can contact us through our website, provide your design specifications, and our team will offer a tailored solution with pricing and lead time estimates.

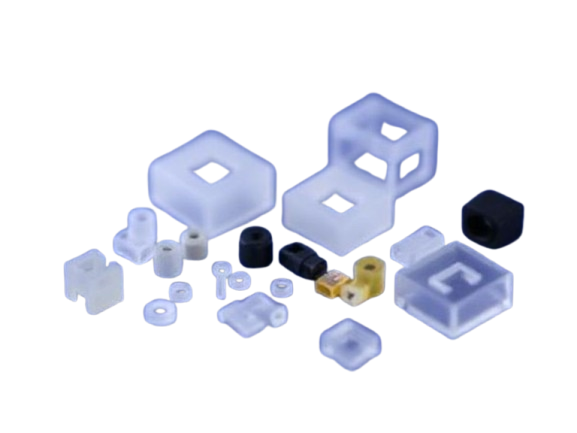

Achieving high precision and mass production of mini-sized plastic elements is not a problem! Gree-Ge provides sophisticated Micro Molding services that are perfect for miniature parts procurement. Submit your file for quotation now and see how much you can immediately save!

Micro Molding Injection has extensive investments in precision micro molding for small and sophisticated components with very close precision tolerances. Our micro-molding capabilities extend to medical devices, microelectronics, automotive sensors, and industrial high precision components.

Micro molding is an advanced form of injection molding used to create miniature and precise plastic components. It permits the integration of micro-scale features, fine details, and thin walls in high precision plastic parts utilized in the medical, electronics, and high-tech industries.

Gree-Ge for Micro Molding services focuses on high precision ultra-small plastic components with tight tolerances. Our micro molding processes ensure superior quality, detail, and repeatability for highly demanding applications.

Our Micro Molding materials offer a wide range of options, are certified, and environmentally friendly, providing premium solutions for your products. Contact us now to learn more!

A high-quality, smooth machine finish is applied to tiny molded parts, improving their surface appearance.

Micro-molded parts can be electroplated with metals like nickel or gold to enhance durability and appearance.

Fine abrasive beads are used to create a uniform matte or satin finish.

Custom textures are applied to the mold surface, transferring to the micro part, creating patterns for functional or aesthetic reasons.

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

Micro molding manufacturing operates as an innovative production method which allows companies to create tiny plastic components with exact dimensions. Now the industries require diminutive sophisticated parts and micro molding serves as their vital solution within medical equipment manufacturing, electronics and automotive sectors.

Gree-Ge delivers high-quality micro molding solutions through which we provide clients with dependable precision components designed to match their precise needs.

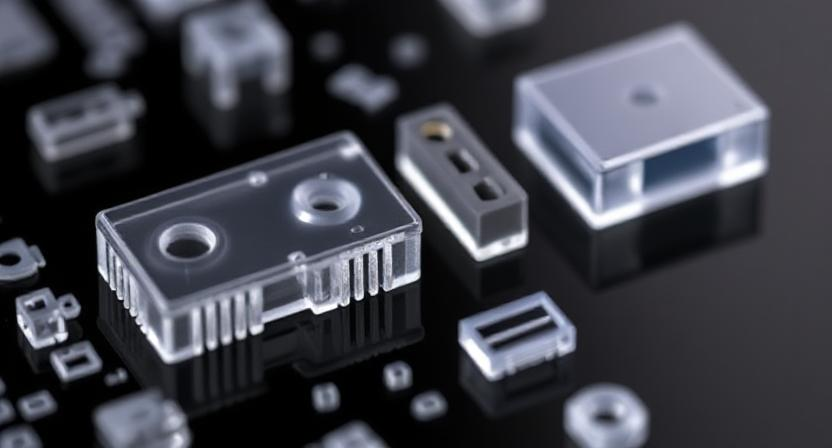

Micro molding works as a particular injection molding technique which enables manufacturers to make small plastic pieces that weigh less than one gram each. Modern micro molding demands state-of-the-art equipment and top-quality tooling systems and specialized polymers to reach its maximum precision.

Standard molding techniques are unable to achieve the necessary level of detail so this process becomes essential. Companies working with Gree-Ge can get miniaturized components that have high complexity together with top-quality dimensional stability.

Through micro molding operations, manufacturers can deliver components with production tolerances that reach plus or minus 0.001 inches. Industries focused on medical devices need this degree of accuracy because any minor product performance change becomes crucial.

The production costs remain affordable because micro molding involves minimal material waste and quick cycles alongside reduced need for additional operation steps. Expanded mold cavities result in additional enhancements of production speed.

Micro molding allows manufacturers to deliver large production volumes of uniform micro parts at affordable prices through its capacity for producing thousands and even millions of identical micro parts with consistent quality.

Micro molding enables producers to use PEEK LCP and high-performance engineering polymers alongside other thermoplastics for custom material requirements in specific applications.

Micro molding technology produces features such as intricate structures with thin wall dimensions as well as undercuts and micro-sized characteristics beyond standard milling capabilities.

The medical device industry needs micro-sized components which should be biocompatible while maintaining precise manufacturing specifications. The production through micro molding yields:

The development of small electronic devices strongly relies on micro molding technology to produce elements such as:

The automotive sector uses micro-molded parts as sensors and safety systems and fuel system components to function properly.

The aerospace and defense sector gets assistance from micro molding technology to produce strong and lightweight components among others.

Designers create specific details in the first stage which verifies that micro components fulfill all functional standards and dimensional targets. Selecting materials remains essential since this choice directly influences the length of part lifespan and its ability to stretch and endure heat.

Custom micro-molds need to be manufactured with precise accuracy through advanced CNC machining combined with EDM (Electrical Discharge Machining) techniques because micro molding requires such high precision.

The micro molding machine operates through high-pressure injection of molten plastic into the micro-mold. The quick cooling process leads to both short cycle duration and enhanced repeatability levels.

Affiliation of small material amounts requires exact flow regulation to prevent manufacturing defects. The company applies combination simulation software together with precision injection systems to create uniform material flow throughout the process.

Micro molds demand tolerances that need to be within three microns. The company utilizes high-precision machining equipment together with strict testing processes that produce faultless mold quality.

Checking parts for defects becomes difficult because they exist at microscopic levels. Gree-Ge uses strict inspection systems based on high-magnification imaging with non-contact measurement techniques to achieve top-quality results.

At Gree-Ge, we are committed to delivering top-tier micro molding solutions to meet the evolving demands of modern industries. Contact us today to explore how our expertise can bring your micro components to life with unmatched precision and efficiency.

You can contact us through our website, provide your design specifications, and our team will offer a tailored solution with pricing and lead time estimates.

Yes, micro molding is ideal for high-volume production, providing consistent quality and cost efficiency across large production runs.

Micro molding operates on a much smaller scale, requiring specialized machines, tooling, and processing techniques to achieve extreme precision.

Common materials include PEEK, LCP, nylon, and high-performance thermoplastics.

Micro molding can produce parts as small as 0.1 milligrams with feature sizes in the micron range, depending on the material and design complexity.