Common metals include aluminum, copper, brass, steel, and magnesium.

Want custom metal profiles engineered with attention to detail like never before? With Green-Ge’s Metal Extruding services, you get quick and affordable engineering manufacturing. Get a quote now by uploading your design.

Gree-Ge provides top-notch services in metal extrusion machining by delivering custom shapes, differing dimensions and excellent mechanical specifications. Our process guarantees the production of high-strength components that are also lightweight and suitable for aerospace, automotive, construction, and other industrial uses. Cost-effective die molds with advanced engineering add-ons deliver affordable and scalable prototypes and mass-produced products alike. Worry not, we have it all under our control.

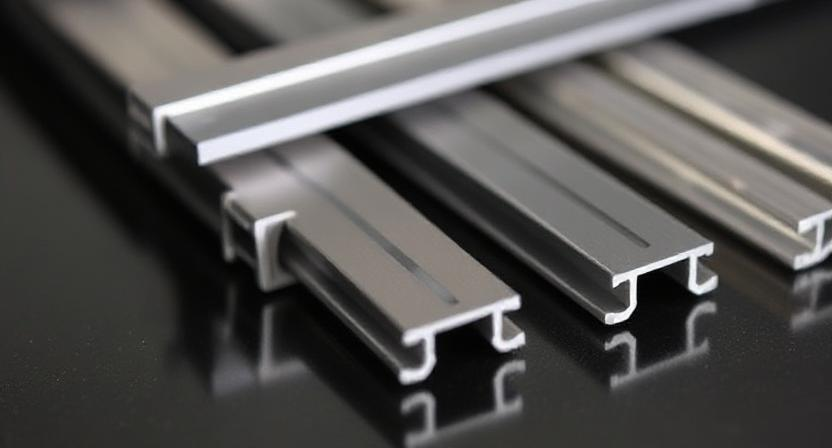

Metal extrusion is the process of manufacturing by which heated or unheated metal is compressed through a die to form a semi-finished product with a constant cross-sectional profile. It is used extensively for the fabrication of parts such as tubes, rods, channels and various other structural components while maintaining excellent strength, exceptional finishes, and very little material waste.

Take advantage of Metal Extrusion services offered by Gree-Ge, specializing in high precision, continual solidification of complex profiled metal structures. Whatever the industry, we pioneer deliver precise metal components with cost effective production, unparalleled strength, and uniformity.

Versatile alloy with high structural strength, toughness, and weldability.

Economical heat treatable alloy ideal for extrusions, with excellent finishing capabilities.

The finish remains unprocessed with surface roughness typically between 64µin – 125µin Ra, and may feature visible grain lines or streaks.

Powdered paint is electrostatically applied and baked, offering a durable, corrosion-resistant finish in various colors and textures.

Wet paint is applied in various formulations and colors; specify the paint brand and number for accurate matching.

Extruded parts can be plated with electroless nickel, nickel, brass, tin, chrome, chromate, Teflon, silver, or gold.

A chromate conversion coating provides corrosion protection and improved adhesion for paints and primers, while maintaining electrical conductivity.

Parts are tumbled to smooth surfaces and remove sharp edges, suitable for smaller items.

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

In industries where strength, precision, and custom geometry matter, metal extrusion offers a powerful manufacturing solution. Whether you’re building structural components, automotive frames, or custom industrial profiles, Gree-Ge’s metal extrusion services deliver quality and consistency you can count on.

With cutting-edge equipment and expert engineering, Gree-Ge helps businesses create complex metal parts quickly and affordably—turning raw materials into finished products with unmatched precision.

Metal extrusion is a process that forces metal through a die to create objects with a fixed cross-sectional profile. It’s especially useful for making long, continuous shapes like tubes, bars, and channels. The result is a uniform product that maintains structural integrity and dimensional accuracy across its entire length.

At Gree-Ge, we offer both hot and cold metal extrusion, allowing us to handle a variety of metals including aluminum, copper, steel, magnesium, and brass. From initial design to final finish, we tailor every extrusion to meet your specific needs.

Gree-Ge combines technological precision with engineering know-how to produce extruded metal parts for a wide range of applications. Our process is built for efficiency, repeatability, and high-volume production—without compromising quality.

What sets Gree-Ge apart:

With us, your extrusion project is more than just metal—it’s a precise solution engineered for performance.

Our engineers help you choose the best process based on your material, part complexity, and volume needs.

Gree-Ge serves a variety of industries that rely on extruded metal parts, including:

Each application benefits from the strength, uniformity, and customizability that metal extrusion offers.

With Gree-Ge’s extrusion capabilities, you’ll enjoy:

Plus, we provide full support from design optimization to finishing, helping you save time and money while achieving optimal product performance.

At Gree-Ge, we don’t just manufacture parts—we build long-term relationships based on trust, technical excellence, and reliability. Whether you need simple aluminum extrusions or complex high-strength steel profiles, we’ll work closely with you to bring your vision to life with speed and precision.

Common metals include aluminum, copper, brass, steel, and magnesium.

Yes, extrusion is excellent for creating custom cross-sectional profiles with precision

Yes, we design and manufacture custom dies in-house for your unique project needs.

Absolutely, extruded parts offer excellent strength and structural integrity, especially when heat-treated.

Yes, we provide CNC machining, drilling, cutting, and finishing as part of our services.