Need precise,custom-shaped tube cutting? Gree-Ge offers high-quality laser tube cutting services for complex geometries and high-strength materials.Upload your design today and receive a competitive quote!

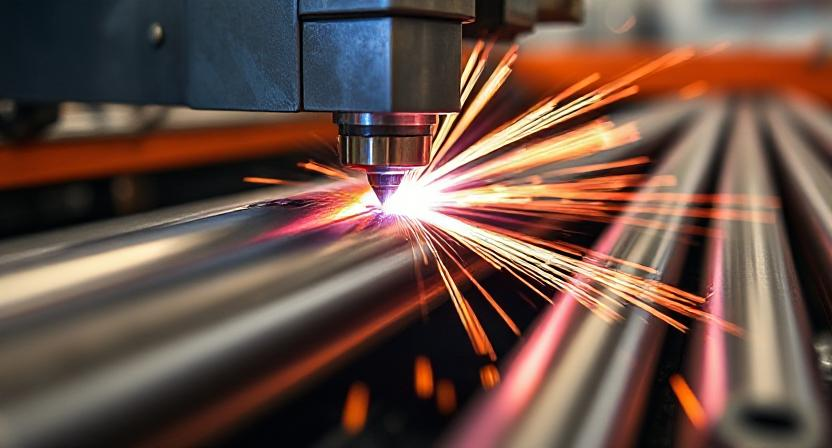

Gree-Ge specializes in automated laser tube cutting,providing clean cuts,tight tolerances,and complex designs for round,square,and rectangular tubing.Our fiber laser technology ensures high-speed,accurate cutting with minimal material waste,making it ideal for automotive frames,medical devices,aerospace structures,and industrial components.

Laser tube cutting is a CNC-controlled process that uses a laser to cut through metal tubing with precision and efficiency. This method allows for complex cuts, chamfers and perforations while maintaining structural integrity and consistency. It is widely used in manufacturing, construction and custom fabrication.

Explore Laser Tube Cutting services by Gree-Ge,delivering high-precision cuts for round,square,and complex-shaped tubes with seamless accuracy.Our laser tube cutting ensures clean edges,tight tolerances,and efficient production for structural applications.

| Feature | Tolerance |

|---|---|

| Cut Edge Orientation | Normal-to-surface (default) |

| Thickness Tolerance | Per raw stock material tolerance |

| Edge-to-Edge Tolerance | ±0.010” nominal (inner face) |

| Holes ≤ 0.100” Diameter | May be slightly oversized |

| Precision Drilled/Machined Holes | Requires manual review |

| Lead-In/Lead-Out Effect | Small bump or edge variation |

| Burr & Tab Removal | Large burrs and tabs removed |

| Discoloration (Halo Effect) | Possible near cut edges |

The cut edges show some discoloration or roughness from the high temperatures of the laser cutting process.

Sharp edges and burrs are removed using mechanical or chemical methods to smooth the surface.

Small glass beads blasted onto the surface to create a consistent matte or satin-like finish.

A rotating abrasive brushing or belt creates a linear texture, removing oxidation and creating a fine matte or satin finish.

Used to smooth rough edges or achieve a precise surface finish, including brushed or polished looks.

An acid bath or electrochemical process is used on stainless steel to remove free iron and improve corrosion resistance.

A laser is used to melt and smooth the surface, reducing roughness and enhancing surface quality.

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!