Yes, we specialize in rapid prototyping to support research, development, and process optimization in the new energy sector.

Discover the precision and reliability of Gree-Ge’s manufacturing solutions for the new energy industry. Reach out today to discuss your project and request a customized quote.

Gree-Ge provides superior manufacturing solutions that produce both high performance and durability together with efficiency for new energy applications. Team Gree-Ge creates superior-quality components that conform to stringent operational requirements of renewable energy applications. Our expert services guarantee exceptional precision and proven reliability throughout all aspects of rapid prototyping and large-scale production of critical energy technologies.

Modern energy sector operations require specialized materials that solve both high-performance specifications and exact engineering requirements as well as exact adherence to official industry guidelines. We provide sustainable high-resistant and energy-efficient components through our extensive experience in solar, wind, hydrogen and battery application manufacturing processes.

The entire production process includes thorough quality inspections which confirm industry standards along with customer requirements.

Reach out to us for quoting your designs or discover our support measures for your energy innovation requirements. The reliability together with performance excellence defines Gree-Ge.

Our expertise spans a wide range of energy solutions, including:

Choose from more than 30 metal alloys and hundreds of industrial-grade plastics.

Improve durability and performance with a selection of finishes

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

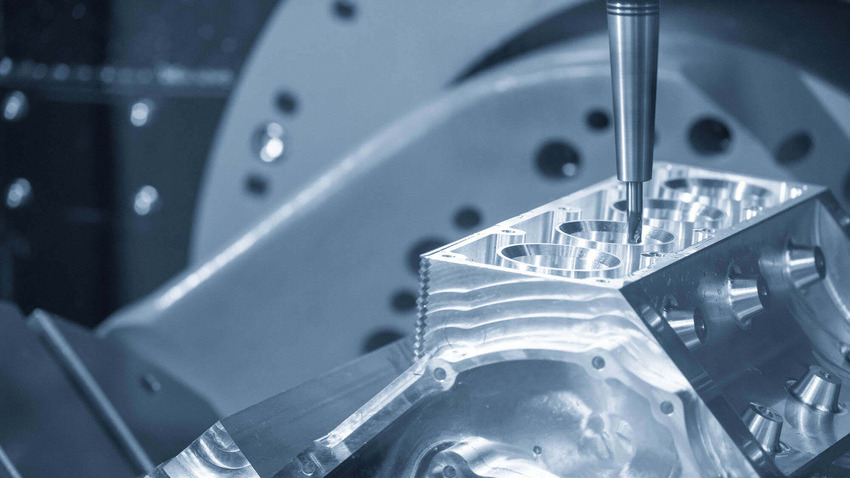

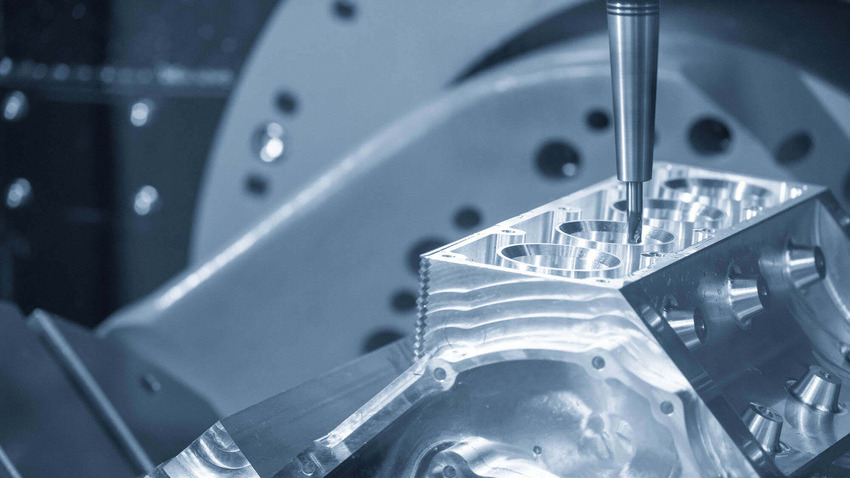

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

Gree-ge delivers top-notch CNC machining with precision, speed, and excellent customer service.

Gree-ge delivers efficient, responsive service with high-quality machining and fast, reliable delivery.

Gree-ge delivers precision, reliability, and exceptional machining quality, exceeding expectations with expert engineering solutions.

The development of clean energy needs advanced manufacturing systems to deliver products that operate efficiently along with durable features and good performance. The entire renewable power generation cycle requires components which achieve maximum precision and reliability levels.

Gree-Ge serves as a leading precision manufacturing supplier to deliver top-quality components which extend the operational life of new energy solutions.

The advancement of renewable energy relies heavily on precision manufacturing because it sustains reliable system output through standardized manufacturing practices. The demanding characteristics of industry performance and material requirements make traditional fabrication methods insufficient thus requiring essential advanced manufacturing techniques.

The development of emerging energy technologies depends on specific materials consisting of high-purity metals and engineered ceramics. The combination of our expertise leads to perfect choices concerning materials along with their processing which results in superior performance.

Renewable energy components need to endure tough operating environments which consist of sustaining high temperature conditions as well as mechanical pressure and exposure to external elements. Our manufacturing precision quality forms components that have extended lifespans.

Complex designs of energy system components become necessary to reach optimal operation and storage capabilities for power conversion processes. Using advanced machining along with fabrication techniques, we execute the generation of challenging shapes while maintaining superior precision.

The modern energy industry advances at a rapid pace so new designs need accelerated development cycles for performance testing. Rapid prototyping capabilities speed up product development time, providing full integration capabilities to new energy systems.

Gree-Ge dedicates itself toward continuous development of precision manufacturing solutions for the new energy sector. Our comprehensive combination of innovative technology and exceptional skills and strict quality assessment measures deliver premium reliability together with exceptional performance to every product we craft. The company reaches the demanding limits of industry standards by using precise engineering methods with knowledge of energy-efficient materials. Our company develops individualized solutions to assist renewable energy projects from rapid prototyping through large-scale commercial production.

Our precision manufacturing approach along with specialized capabilities positions us as the top selection for new energy production.

Do you support prototyping for new energy technologies?

Yes, we specialize in rapid prototyping to support research, development, and process optimization in the new energy sector.

What types of manufacturing services do you offer?

Our company delivers accurate fabrication services together with material transformation and precise manufacturing of components for renewable energy systems.

What quality control measures does Gree-Ge use for energy components?

We implement rigorous testing, including material analysis, dimensional inspections, and environmental stress testing to ensure high performance and reliability.

Can Gree-Ge manufacture components for emerging energy technologies?

Yes, we support innovative energy solutions, providing precision components for hydrogen, advanced battery systems, and next-generation solar and wind applications.

How do you ensure the durability of energy components?

The company applies high-performance materials and advanced surface treatments to strengthen and improve resistance against corrosion in energy environments.