The company produces different medical components that include surgical instruments, implants, diagnostic equipment parts as well as prosthetic components.

Achieve highly precise medical device manufacturing requirements through Gree-Ge’s products. Our team awaits your contact for discussing details about your requirements followed by providing custom quotations.

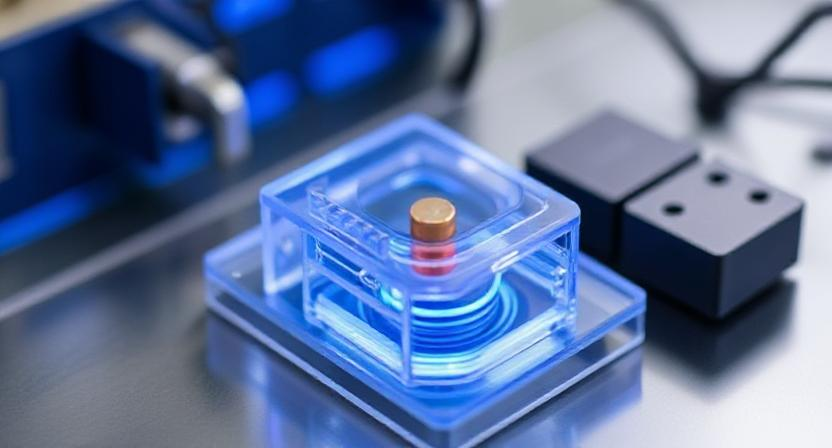

Gree-Ge delivers precision and reliability along with efficiency through CNC machining services targeted for medical applications. The company specializes in producing top-quality medical components which exceed the rigid benchmarks of medical device manufacture. Our advanced production system delivers accuracy together with material compatibility for medical equipment intended for vital applications.

The production of medical devices must follow industry rules while needing superior components alongside exact manufacturing methods. Our years of experience in medical device development and production allows us to manufacture components that fulfill mandatory industry regulations for medical equipment safety and performance reliability. Quality examinations with precise validation components run on every part to confirm medical regulatory standards. Wholesale pricing for your designs along with medical manufacturing assistance is available after you contact us today.

The range of products at Gree-Ge includes biocompatible materials used for implants, precision-machined surgical instruments alongside micro-machined diagnostic equipment components.

Our expertise spans a wide range of medical components, including:

We offer an extensive array of material options, catering to prototyping through full-scale production needs. Choose from more than 30 metal alloys and hundreds of high-performance plastics.

Improve durability and performance with a selection of finishes

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

Gree-ge delivers top-notch CNC machining with precision, speed, and excellent customer service.

Gree-ge delivers efficient, responsive service with high-quality machining and fast, reliable delivery.

Gree-ge delivers precision, reliability, and exceptional machining quality, exceeding expectations with expert engineering solutions.

Medical components that include life-saving implants and intricate surgical instruments need to achieve the maximum standards of performance safety and durability.

The company, Gree-Ge establishes leadership in medical CNC machining to manufacture high-precision parts which advance both medical care and healthcare innovation.

The medical equipment industry relies on CNC machining as its fundamental production method because it delivers necessary precision alongside steadiness for contemporary modern medical devices. The manufacturing industry requires tight tolerances and biocompatibility standards that traditional methods cannot achieve which makes CNC machining the selected manufacturing process.

Extreme precision standards apply to medical components since these factors determine both functionality and patient protection. CNC machining produces precise specifications which reduces errors while meeting all necessary regulatory requirements.

A wide range of medical devices require elaborate shapes as well as intricate details. Our CNC machinery with multi-axis functionality produces extremely precise complex parts accurately.

Medical devices need materials which offer protection from exposure to humans and deflagrate mineral corrosives while maintaining their structural integrity. Through CNC machining operators can fabricate medical-grade materials such as titanium stainless steel PEEK and other titanium materials.

Rapid prototyping needs in medical R&D depend on CNC machining because engineers can execute multiple design evaluation rounds to verify their products before commercial release.

Gree-Ge produces various necessary medical parts that include:

Medical procedures gain accuracy and reliability through precision surgical tools which include tools such as forceps, clamps and scalpels.

The quality standards of CNC machining produce medical implants such as orthopedic and dental components which uphold proper fit with material biocompatibility for extended clinical applications.

The components used in MRI scanners and CT scanners along with diagnostic medical devices must have both high precision manufacturing and extended durability.

The enclosures manufactured by CNC machines protect medical electronics against environmental conditions and defend patient health.

The medical industry advances its healthcare technology by using CNC machining as one of its vital components.

AI-powered CNC machines together with robotic automation and IoT integration systems promote medical manufacturing efficiency as well as consistency while providing traceability to the manufacturing process.

CNC technology improvements enable the creation of small but extremely precise components that healthcare professionals use during minimally invasive surgeries.

Medical devices obtain superior performance while gaining better wear resistance and biocompatibility through the utilization of specialized coatings and surface treatments.

Environmental and energy-efficient production methods alongside recyclable material use enable sustainable manufacturing of medical products.

Gree-Ge maintains a dedication to give medical industry-specific CNC machining services that deliver premium quality results. Our commitment to exactness combined with adherence to standards and continuous innovation enables us to be a dependable manufacturing company for medical devices.

Partner with Gree-Ge to receive medical components specifically created for safety combined with performance and reliability standards.

The company produces different medical components that include surgical instruments, implants, diagnostic equipment parts as well as prosthetic components.

Absolutely. We adhere to ISO 13485 and FDA standards to meet the stringent requirements of medical device manufacturing.

Gree-Ge excels at creating custom CNC machines specialized for medical device producers who require exact solutions within regulatory requirements.

Yes, we offer rapid prototyping services to help validate designs before full-scale production.

Yes, we have the capacity to support both small and large-scale production runs while maintaining strict quality control.