Our company specializes in producing aerospace-grade materials that consist of aluminum alloys together with titanium, stainless steel and high-performance plastic materials

Discover the precision and performance of Gree-Ge for your aerospace projects. Contact us today to discuss your requirements and request a free quote.

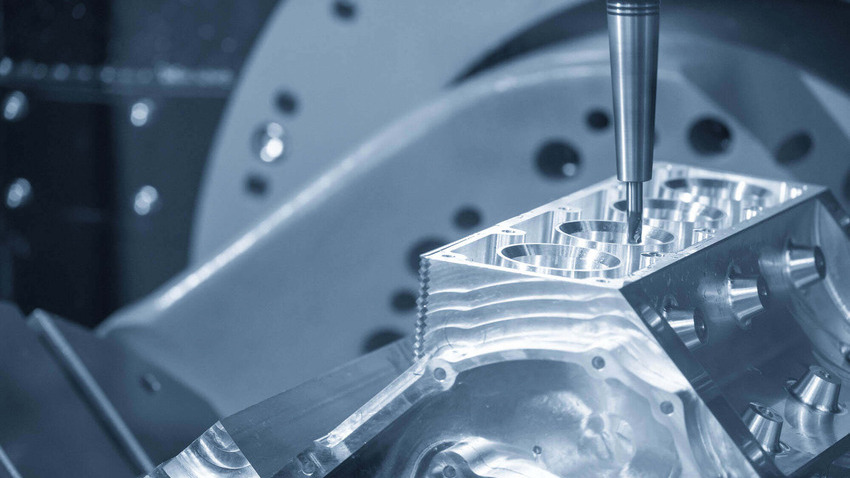

Experience unparalleled accuracy and dependability with Gree-Ge’s aerospace CNC machining services. We focus on creating highly engineered parts that fulfill the demanding requirements of the aerospace industry. Irrespective of whether it is prototyping or large volume machining, our sophisticated machining capabilities guarantee quality, efficiency, and precision to aerospace standards

The aerospace prototyping process requires precision alongside quality production and strong adherence to all specifications. Gree-Ge with it’s aerospace CNC machining expertise create aerospace components ranging from straightforward to intricate pieces precisely. The company maintains strict quality control methods together with industry certification requirements that produce parts meeting exceptional standards.

Your aerospace application needs lightweight as well as heat-resistant alloys so Gree-Ge is here to provide exact manufacturing solutions.

Our expertise covers a wide range of aerospace components, including:

We offer 30+ metal alloys and hundreds of high-performance plastics for prototyping to full-scale production, with finishing options to enhance durability and performance.

Improve durability and performance with a selection of finishes

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

Gree-ge delivers top-notch CNC machining with precision, speed, and excellent customer service.

Gree-ge delivers efficient, responsive service with high-quality machining and fast, reliable delivery.

Gree-ge delivers precision, reliability, and exceptional machining quality, exceeding expectations with expert engineering solutions.

The aerospace industry uses CNC (Computer Numerical Control) machines to manufacture precise components required for aircraft and spacecraft systems as well as defense operations.

The aerospace industry requires components that maintain exact specifications together with extraordinary resistance to wear and operation under strict quality procedures. CNC machining delivers aerospace components that perform reliably under demanding conditions because it offers exceptional accuracy alongside repeatability alongside efficiency.

The aerospace manufacturing industry relies on CNC Machining to succeed

Aerospace components need precise measurements which need to stay within ±0.001 inch tolerances. Part dimensions which differ from their nominal values even slightly may affect both aircraft performance and safety. Through CNC machining manufacturers achieve exact part production that ensures both accuracy consistency and eliminates human error as well as maintains uniformity in mass production.

Complex designs combined with difficult geometries limit what traditional machining technology can accomplish when creating aerospace parts. How multi-axis CNC machining allows constructors to produce sophisticated shapes using less setup sequences which minimizes manufacturing duration while raising parts quality standards

The components of aircraft and spacecraft need materials that demonstrate superior strength-to-weight relationships along with resistance against corrosion and ability to withstand high temperatures. CNC machining permits manufacturers to operate on various aerospace-grade metals together with advanced composites during production.

CNC machining systems produce diverse essential aerospace elements through their manufacturing process.

The extreme operating environments demand engine components with high precision along with heat-resistance capacity. The CNC process generates turbine blades and combustion chambers and fuel nozzles together with exhaust components which maintain precise tolerances and deliver superb surface quality.

For aircraft structures, engineers craft sturdy components which also need to maintain a low weight. The production of wing spars, landing gear components and brackets as well as wing brackets by CNC machining ensures aircraft structural integrity.

Safety systems for avionics demand custom-made protective containers which shield them from both electromagnetic disruptions and external hazards. CNC-machining of enclosures enables manufacturers to create perfect fit dimensions which protects the functionality of onboard equipment.

Fasteners along with connectors stand as critical elements for assembling airframe components because reliability is essential. The CNC machining process guarantees aerospace quality standards of durability and precision for screws bolts and couplings.

The integration of AI into CNC machines combined with robotic automation features within production areas results in faster operations while eliminating mistakes. These technologies allow for real-time operational oversight through which precision manufacturing reaches its highest levels while increasing productivity measures significantly.

Surface finishing solutions for aerospace components now extend their operational lifetime by applying new techniques to product finishing.

DLC coatings together with ceramic coatings and anodizing treatments provide components with corrosion protection while delivering enhanced thermal resistance and protection.

At Gree-Ge, we implement state-of-the-art CNC systems and multi-axis equipment along with precise quality controls to manufacture aerospace components that exceed industry standards of precision.

Our CNC machining expertise makes us the preferred supplier to aerospace manufacturers who need services for rapid prototyping as well as high-volume production worldwide.

Accurate aerospace development benefits from CNC machining precision. Please contact Gree-Ge for a business discussion about your requirements while obtaining a price quotation.

Our company specializes in producing aerospace-grade materials that consist of aluminum alloys together with titanium, stainless steel and high-performance plastic materials

The CNC technology at our workplace enables us to accomplish tight tolerances down to ±0.001 inches.

Absolutely. Our precision and reliable operations follow standards based on both AS9100D and ISO 9001 requirements.

Our products ship according to the complexity of each project though we maintain fast-track procedures for emergency requests.

Yes, we handle both small and large-scale production while maintaining the quality.