- Home

- »

- For Prototyping

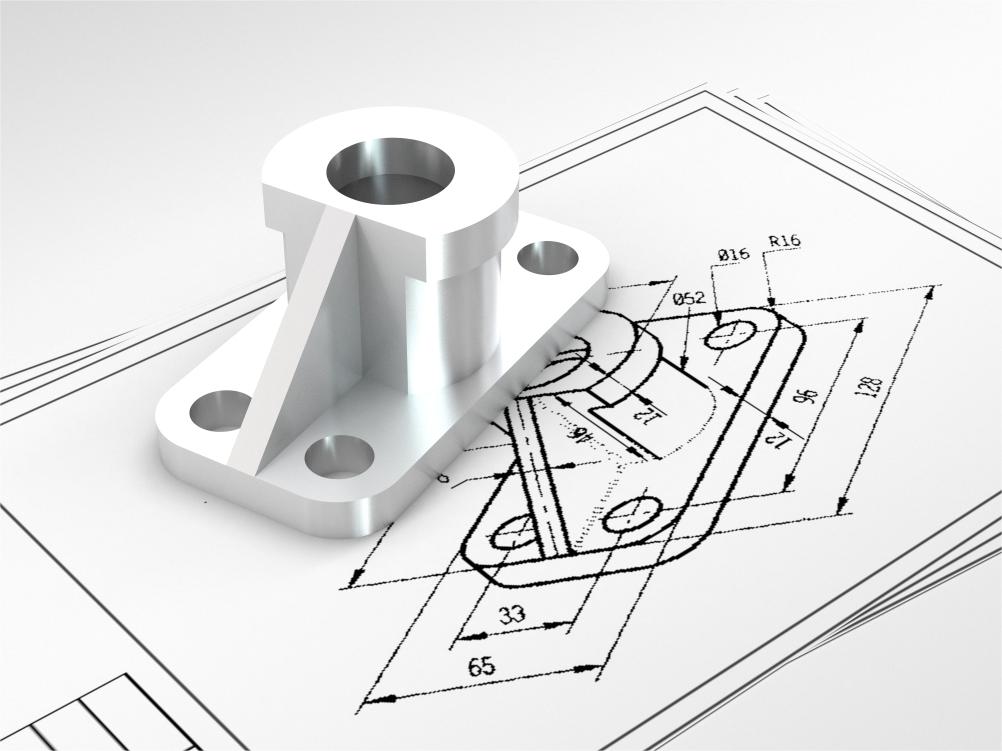

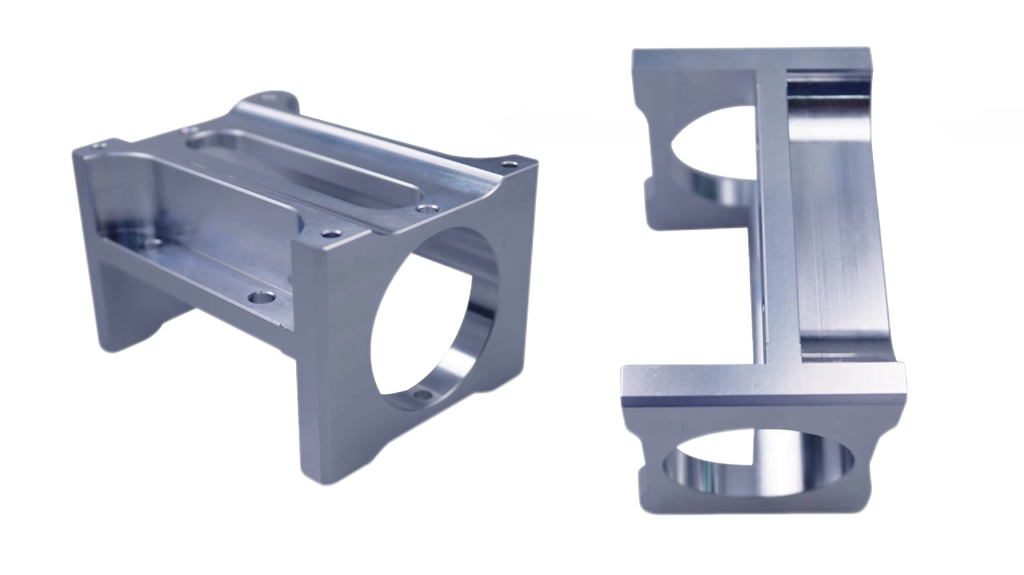

Rapid Prototyping Machining

One-stop for all your prototyping and manufacturing needs, Gree-Ge prototyping services ensure rapid machining, reliable, and cost-effective solutions

- All uploads are secure and confidential

Prototyping Service

| Service | Features | Fastest Lead Time |

|---|---|---|

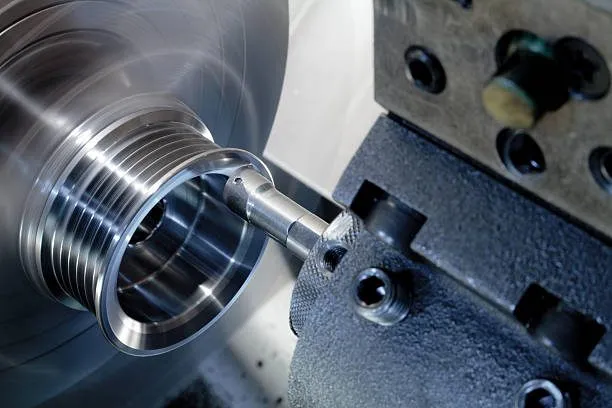

CNC Prototyping | 1. High precision and repeatability 2. Suitable for complex and precise parts 3. Works with a variety of materials including metals and plastics 4. Ideal for low to medium volume production | 2-5 days |

3D Printing Prototyping | 1. Rapid prototyping 2. Suitable for complex geometries and small batch production 3. Supports various materials including resin, nylon, and metal powders 4. No need for molds, reducing initial preparation time | 1-3 days |

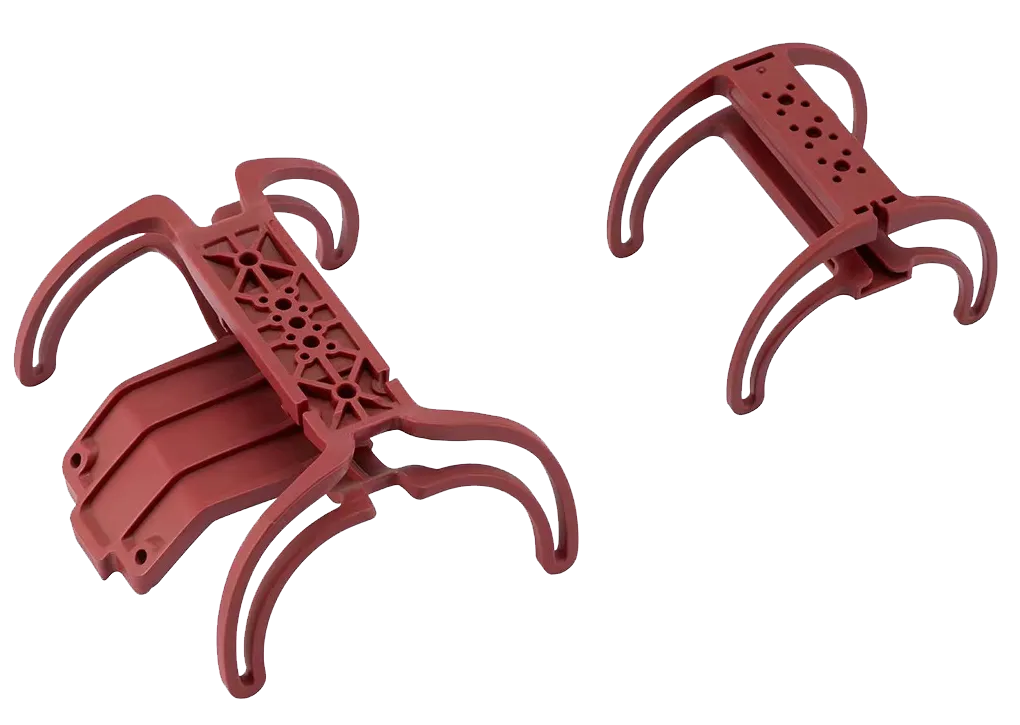

Injection Molding Prototyping (T1 Samples) | 1. Ideal for plastic parts, especially complex shapes 2. Quick mold technology allows limited quantity of prototype parts in a short time 3. Highly automated, suitable for large volume production | 1-4 weeks |

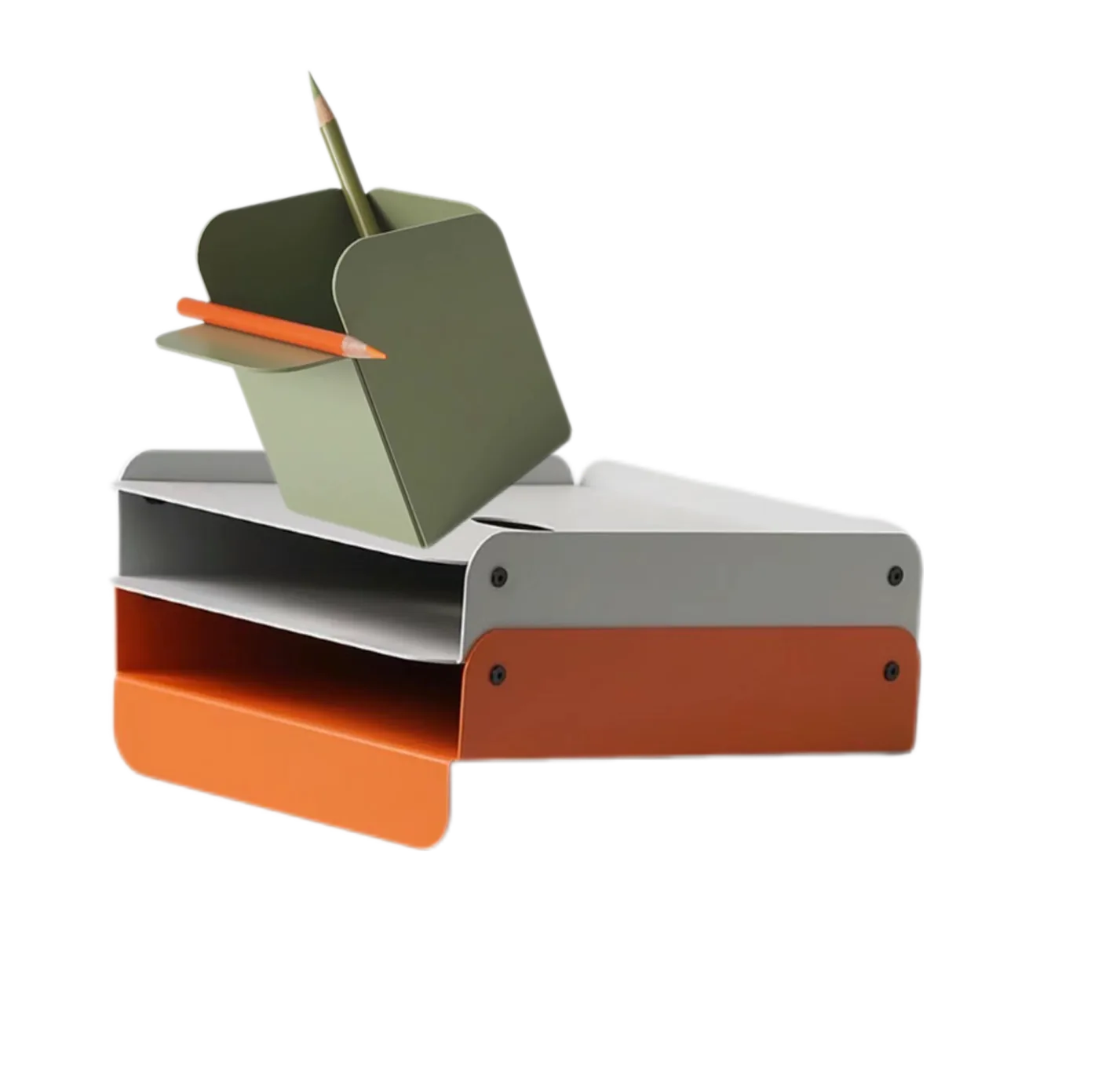

Sheet Metal Prototyping | 1. Suitable for manufacturing prototypes from metal sheets such as enclosures, brackets, and housings 2. Provides quick and flexible manufacturing options 3. Supports various metal materials including aluminum, stainless steel, and carbon steel | 5-7 days |

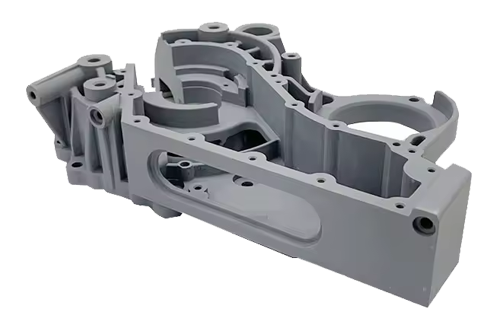

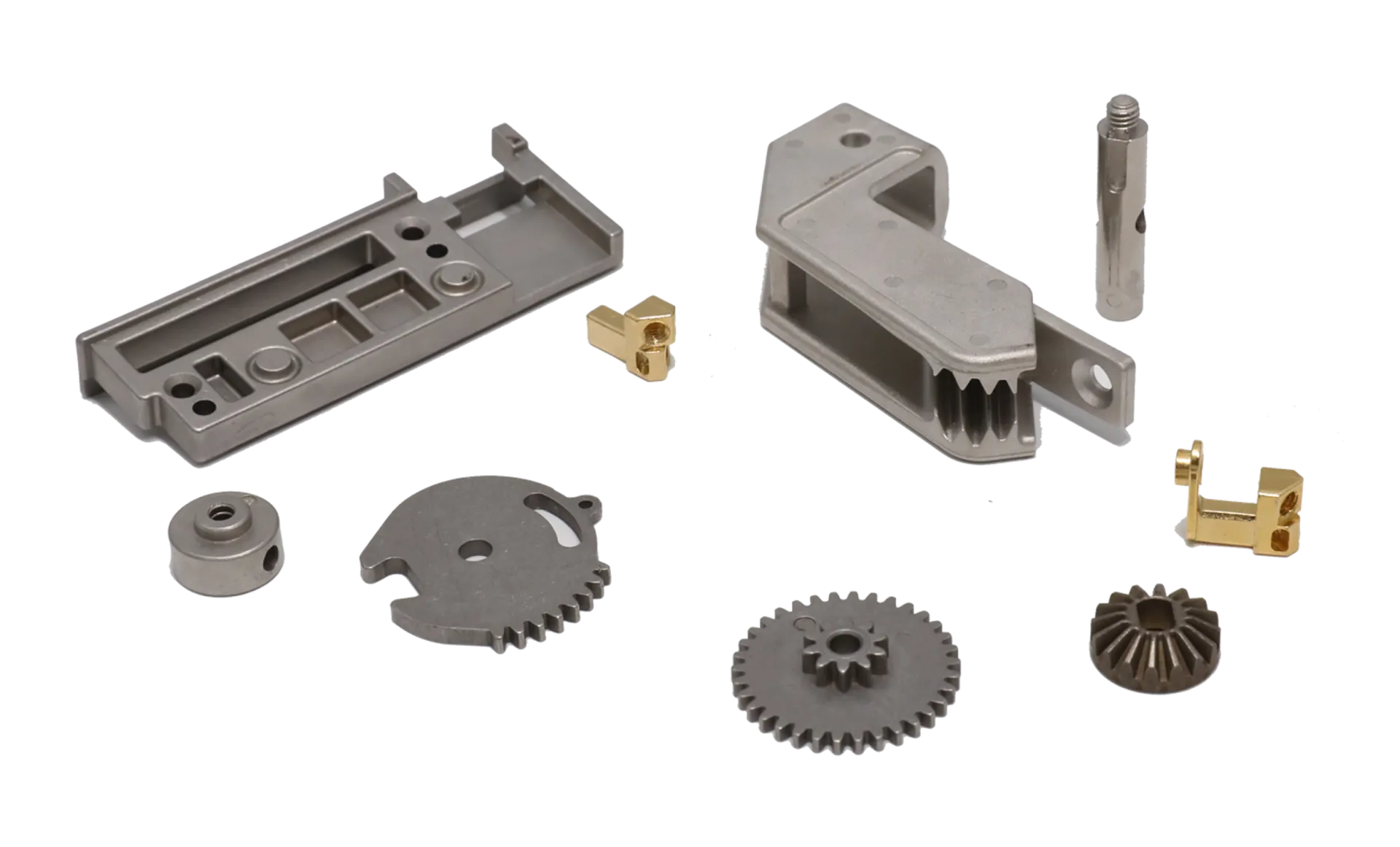

Precision Manufacturing Capabilities

Unlock high-quality, efficient, and cost-effective precision manufacturing solutions, including CNC machining, injection molding, die casting, 3D printing, and sheet metal fabrication—tailored for prototypes and production.

- Precision Cutting:

- Tight tolerance

- Material Versatility:

- Various metals

- Surface Finish:

- Smooth polish

- Production Speed:

- Rapid turnaround

- Layering Process:

- Sequential deposition

- Material Options:

- Polymers, metals

- Design Flexibility:

- Complex shapes

- Surface Finish:

- Post-processing needed

- Material Types:

- Steel, aluminum

- Strength Level:

- High durability

- Surface Finish:

- Polished, coated

- Heat Resistance:

- High temperature

- Material Types:

- ABS, polycarbonate

- Surface Finish:

- Glossy, textured

- Production Scale:

- Low to mass

- Precision Requirement:

- Tight tolerance

- Manufacturing Process:

- Cutting, bending

- Material Types:

- Metal, plastic

- Surface Finish:

- Polished, coated

- Precision Requirement:

- Tight tolerance

- Design Support:

- DFM optimization

- Surface Enhancement:

- Anodizing, plating

- Quality Assurance:

- Inspection, testing

- Packaging Options:

- Custom labeling

Bring Your Designs to Life with Gree-Ge

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

- Expertise Shared Widely

- Market Reach Expanded

- Advanced Technology Integrated

- Collaborative Innovation Opportunities

- Reliable On-Demand Solutions

- All uploads are secure and confidential

Why Choose Us

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

From Prototyping to Mass Production

For Prototyping

For Prototyping

- What is prototyping?

Prototyping is the process of creating an early sample or model of a product to test its design, functionality, and feasibility before mass production.

- Why is prototyping important?

Prototyping machining helps identify design flaws, test functionality, and gather feedback, which allows for improvements before committing to large-scale manufacturing, saving time and costs.

- How do I get started with my prototyping project?

To get started, contact us with your project details, including design files and specifications. Our team will review your requirements and provide you with a quote and timeline.

- What is a T1 sample in injection molding?

A T1 sample is the first trial sample produced from a new mold in the injection molding process. It is used to evaluate the mold and make necessary adjustments before mass production.

- Do you offer rapid prototyping?

Yes, we offer rapid prototyping services, including 3D printing and CNC machining, to provide quick turnaround times and meet tight project deadlines.

- What is the cost of prototyping?

The cost of prototyping depends on factors such as the complexity of the design, materials used, and the type of prototyping service. Contact us for a detailed quote based on your specific requirements.

- Can you help with the design of my prototype?

Yes, we provide expert design support to help optimize your prototype for manufacturability, ensuring the best quality and performance.

- What types of prototyping services do you offer?

We offer CNC prototype service,3D printer prototype service, injection molding prototype(T1 samples), and sheet metal prototype to meet various prototyping needs.

- How long does it take to create a prototype?

The lead time for creating a prototype varies depending on the complexity and type of service. For example, CNC machining and 3D printing can produce prototypes in as fast as 1-3 days, while injection molding may take 1-4 weeks.

- What materials can be used for prototyping?

We offer a wide range of materials for prototyping, including metals, plastics, and composites. Specific materials include aluminum, steel, ABS, nylon, and more.