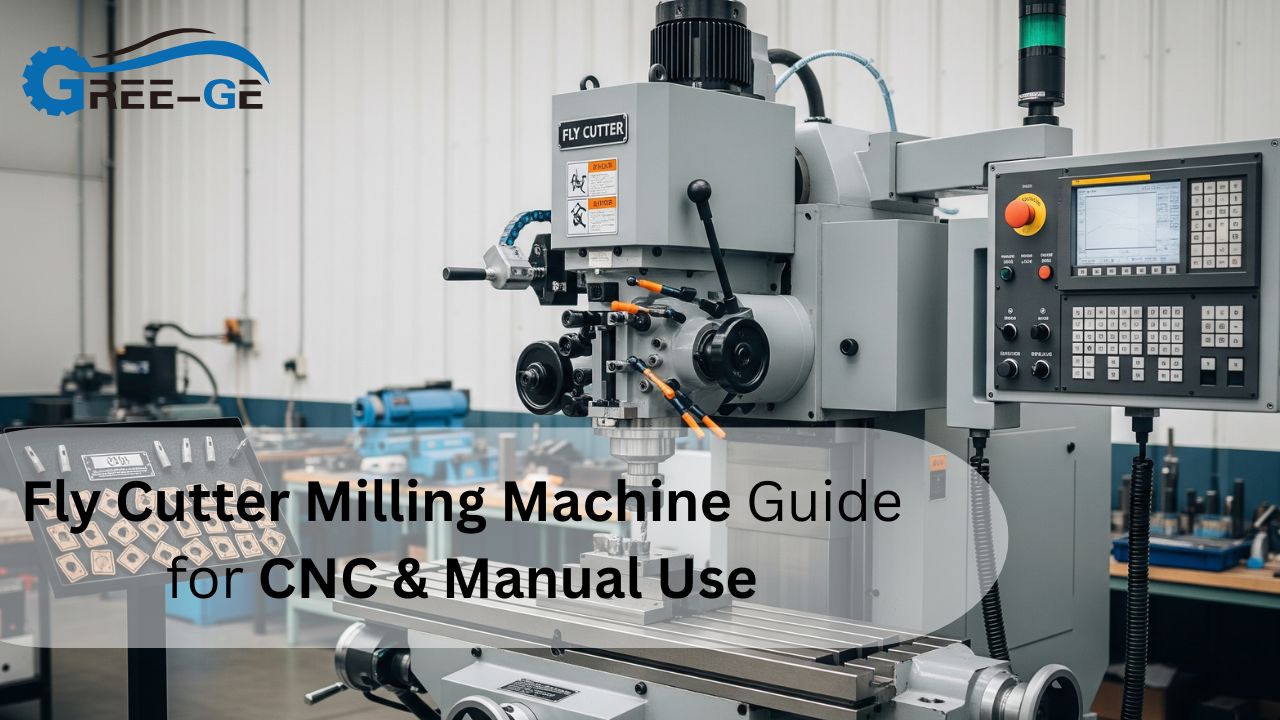

A fly cutter milling machine is a simple yet powerful tool used in metalworking. It is widely used to create flat surfaces with high precision. Unlike complex tools, a fly cutter uses a single-point cutting tool. This makes it easy to operate and maintain. Even beginners in machining can understand its use. This machine is often used in combination with a CNC milling. It can help shape metals, plastics, and other hard materials.

What Is a Fly Cutter Milling Machine?

A fly cutter milling machine is a type of rotary cutting tool. It has a single or multiple cutting edges that spin while the workpiece stays fixed. It is mounted on the spindle of a milling machine. As it rotates, it cuts across the material to create flat surfaces. It is often used for facing operations. Compared to multi-point tools, it offers more surface area per cut. This leads to better finishing and lower machining costs. In CNC machining, fly cutters are also used for finishing flat faces.

Key Features of Fly Cutter Milling Machine

The fly cutter milling machine has several simple but useful features. It has a single cutter that makes replacement of tools easy. The cutter head will be adjustable; it can make various widths of cut. When you want a smooth surface of broad area it is very useful. It also minimizes the wear and tear of tools which saves money in the long run. A fly cutter works well on both manual and milling machine with CNC setups.

Components of a Fly Cutter

A basic fly cutter has a few main parts. These components make it simple to use and maintain:

| Component | Description |

| Cutter Body | The main frame that holds the tool. Usually made from steel or alloy. |

| Tool Bit Holder | Holds the plasma cutting machine tool. Often adjustable for depth and angle. |

| Cutting Tool (Bit) | The actual tool that makes contact with the material. Often made of carbide. |

| Arbor or Shank | The connecting shaft that mounts onto the spindle. |

| Locking Screws | Used to secure the tool bit and body during operation. |

These parts are easy to assemble and replace. That’s one reason why fly cutters are so popular in workshops and CNC milling machine environments.

Benefits of Using Fly Cutter Milling Machine

Using a fly cutter milling machine has many benefits. It’s ideal for surface finishing and gives very flat results. The tool is simple, so it’s easy to control. It costs less than other tools that provide the same surface quality. Fly cutters are perfect for low-volume production. If you’re not running a large factory, this machine still gets the job done. Even in a milling machine with CNC, it performs efficiently with minimal setup. Some of the main benefits include:

- Lower cost

- High-quality surface finish

- Wide cutting area

- Easy tool maintenance

- Suitable for many materials

Using Fly Cutters with CNC Machines

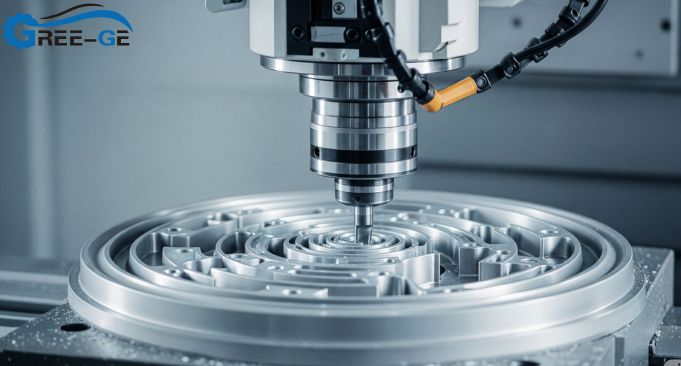

In modern CNC machining, fly cutters are often used for facing large areas. The CNC machine ensures the cutter moves in a straight and controlled path. This improves accuracy and repeatability. When paired milling machine with CNC, fly cutters become more efficient.This reduces human error and gives consistent results. CNC machines also allow you to save settings for future jobs. If you work with flat parts or molds, this combination can be very useful. Many machine shops use them for prototypes and custom parts.

Comparison Table: Fly Cutter vs Face Mill

Here’s a helpful table to compare fly cutters and face mills. This can help you decide which tool suits your needs.

| Feature | Fly Cutter | Face Mill |

| Cutting Edges | Single or dual point | Multiple (4–12 inserts) |

| Surface Finish | Very smooth | Smooth but slightly less than fly cutter |

| Cost | Low | High |

| Ideal Use | Flat finishing, low-volume work | High-volume, heavy-duty jobs |

| Maintenance | Easy (one tool bit to replace) | Harder (multiple inserts) |

| Speed | Slower | Faster |

| Machine Compatibility | Manual and CNC milling machine | Mostly CNC machines |

Components of CNC Milling Machine

To understand how fly cutters work with CNC, you should know the main components of CNC milling machine:

- Spindle: Holds and rotates the tool.

- Control Panel: Interface for entering commands.

- Coolant System: Reduces heat and extends tool life.

- Motor & Drive: Powers the spindle and controls motion.

These parts work together to give you precise cuts. When a fly cutter is used, it mounts on the spindle. The motion is controlled through the CNC software.

Best Practices for Using a Fly Cutter

Here are a few tips to get the best results:

- Use low RPM: Too much speed can cause chatter.

- Make shallow cuts: This helps get a smoother finish.

- Tighten all screws: Loose parts can lead to bad results.

- Use coolant: Reduces heat and improves tool life.

- Set correct angle: Adjust for the material type.

Always follow safety procedures when using the machine. Wear goggles and gloves, and make sure the workpiece is tightly clamped.

Applications of Fly Cutter Milling Machine

The fly cutter milling machine is used in various industries. It’s common in mold making, automotive, and aerospace. It’s perfect for smoothing out cast parts or creating flat patterns. In CNC machining services, it is also used in the final steps of part finishing. It’s ideal for removing small layers and evening out surfaces. You’ll find it in both large factories and small workshops. Typical uses include:

- Flat surface finishing

- Deburring

- Mold base leveling

- Fixture plate preparation

- Custom part shaping

Final Thoughts

A fly cutter milling machine is cheap and easy to use. It provides a smooth surface finish and it is considered to be compatible with manual and CNC milling machines. Setting up, maintenance, and operation is simple. This tool can be valuable to you whether you are new to CNC machining or an expert at metalwork. It is cheap and efficient to use in any size of a workshop. In addition, the fly cutter is a smart idea, if you are willing to level large surfaces, minimize tool wear and save money.

FAQs

Can I use a fly cutter on aluminum?

Yes, fly cutters work well on aluminum and provide a mirror-like finish.

Is a fly cutter safe for beginners?

Yes, it’s simple to operate but should be used with care and safety equipment.

What speed should I use for fly cutting?

Lower RPMs are recommended—typically between 300 to 800 RPM depending on the material.

Tell me how I can differentiate between a fly cutter and a face mill?

A fly cutter has a single-point cutting tool, ideal for smooth finishes, while a face mill has multiple inserts and is better for high-speed, heavy-duty cutting.