Standard lead time is 10–15 business days, depending on part complexity and volume.

Gree-Ge delivers high-quality custom metal and plastic die-cast parts with fast lead times and free standard shipping. Our manufacturing network is ISO 9001:2015, ISO 14001, IATF 16949:2016, and ISO 13485 certified, ensuring compliance with the highest industry standards.

At Gree-Ge, we provide a seamless, efficient die-casting service tailored for engineers, designers, and manufacturers. Whether you need rapid prototypes or full-scale production, our extensive manufacturing network ensures high-quality results at competitive prices.

With our instant quoting system, you can upload a CAD file and receive real-time pricing and lead times, streamlining your manufacturing process. We offer various finishing options, including anodizing, powder coating, and plating, to meet your application’s exact requirements.

Upload your CAD file now for an instant quote and bring your designs to life with precision die casting.

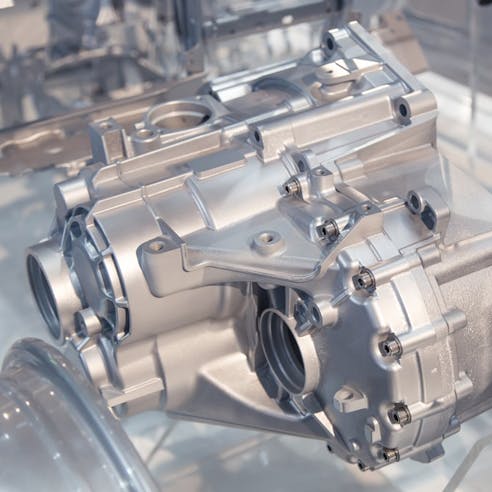

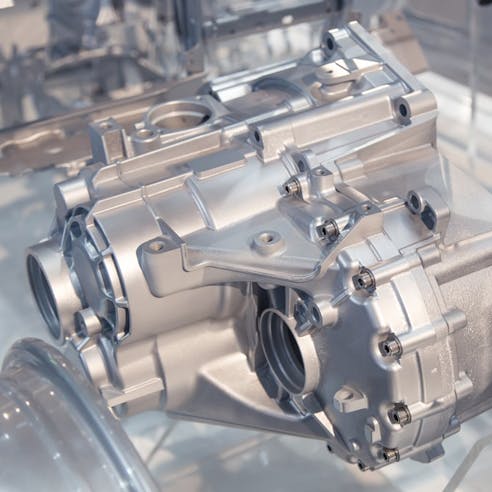

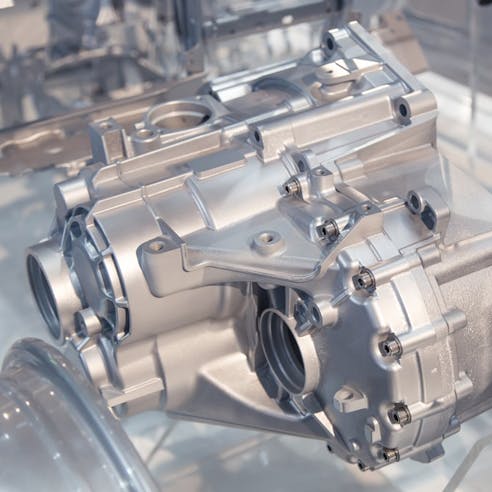

Die casting is a precision metal manufacturing process that uses high-pressure injection to mold molten metal into complex, high-strength components. This process delivers exceptional accuracy, repeatability, and durability, making it ideal for industries such as automotive, aerospace, electronics, and medical devices.

Die casting can produce lightweight yet strong parts with excellent surface finishes, reducing the need for secondary machining. Common materials include aluminum, zinc, and magnesium, each offering unique benefits for strength, corrosion resistance, and thermal conductivity.

High-precision metal casting solutions for durable and complex parts. Achieve superior strength, tight tolerances, and cost-effective production with advanced aluminum, zinc, and magnesium die casting techniques.

Advanced die casting techniques ensure precision and durability for complex metal parts.

High-quality aluminum, zinc, and magnesium alloys for strong and lightweight components.

Expert mold design and fabrication for consistent, high-performance casting production.

High-precision metal casting solutions for durable and complex parts. Achieve superior strength, tight tolerances, and cost-effective production with advanced aluminum, zinc, and magnesium die casting techniques.

Advanced die casting techniques ensure precision and durability for complex metal parts.

High-quality aluminum, zinc, and magnesium alloys for strong and lightweight components.

Expert mold design and fabrication for consistent, high-performance casting production.

| Feature | Description |

|---|---|

| Maximum Part Size | Up to 24” x 24” x 12” (610 x 610 x 305 mm), depending on the material and design complexity. |

| Standard Lead Time | 10–15 business days, depending on part complexity and volume. |

| General Tolerances | Standard tolerances held to ±0.005” (±0.127mm) for metals, in accordance with ISO2768-M. |

| Precision Tolerances | Tighter tolerances down to ±0.002” (±0.051mm) are achievable upon request, depending on part geometry and material. |

| Minimum Wall Thickness | Typically 0.020”–0.060” (0.50–1.50mm), depending on alloy and design. |

| Draft Angle | Standard draft angles of 1° to 3° are applied to ensure proper mold release. |

| Threads and Tapped Holes | Standard and custom threads are available; inserts can also be integrated for enhanced durability. |

| Surface Finish | As-cast surface finish is typically 125–300 Ra. Additional finishing options include polishing, powder coating, anodizing, and plating. |

Zinc and aluminum zinc parts can be left as-cast and retain reasonable corrosion resistance. Aluminum parts must be coated to achieve corrosion resistance. Cast parts are typically broken away from the casting sprue, leaving rough marks at the gate locations. Most castings will also have visible marks left by the ejector pins. The surface finish for as-cast zinc alloys is commonly 16-64 microinch Ra.

The part surface is left with a smooth, matte appearance.

Aluminum is typically anodized. Type II anodizing creates a corrosion-resistant oxide finish. Although suppliers can anodize parts in different colors, the surface of a die cast part does not facilitate a cosmetic finish with anodizing. Type III is a thicker finish and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. Anodized coatings are not electrically conductive.

| Category | Locking Force Range (Tons) | Size Range (mm) | Our Equipment | Applications | Key Advantages |

|---|---|---|---|---|---|

| Small Precision Parts | 88-300 | Up to 150 | 88 tons, 160 tons, 180 tons | – Electronic product enclosures – Small mechanical components – Precision automotive parts | – Ideal for producing small, detailed parts with high precision – Suitable for high-volume production of small components |

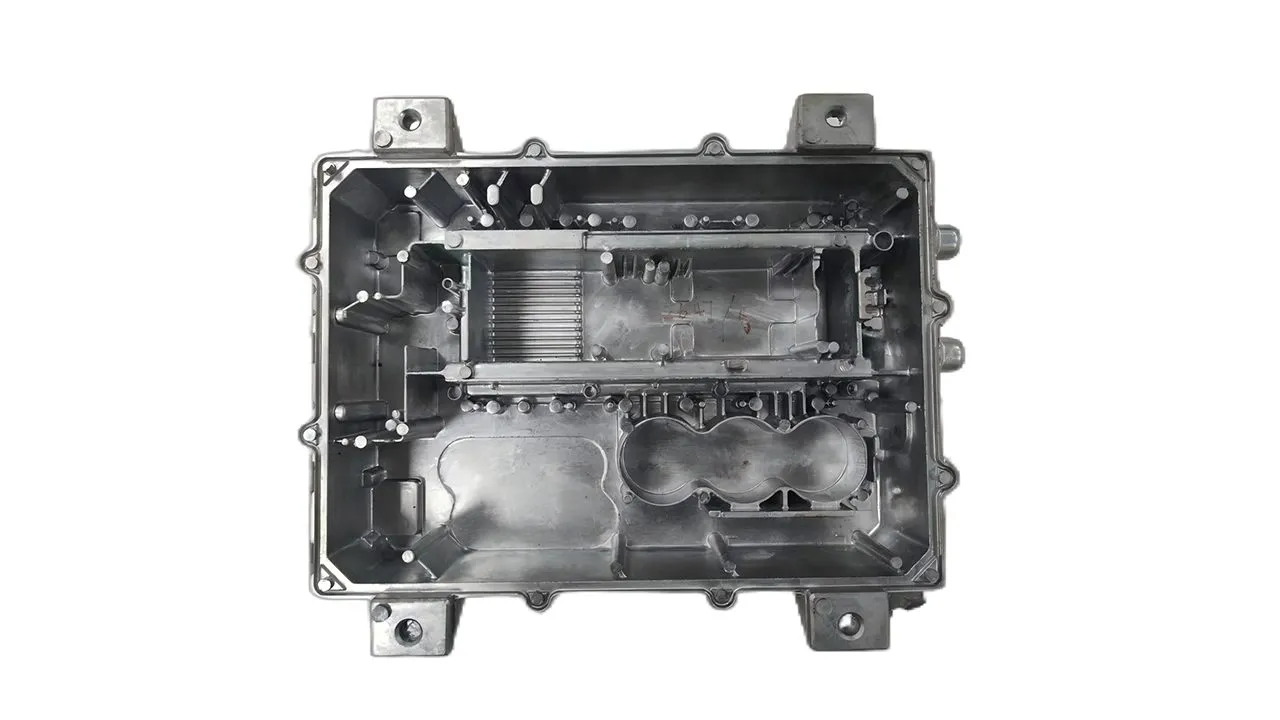

| Medium-Sized Parts | 300-800 | 150-600 | 300 tons, 400 tons, 500 tons, 630 tons | – Automotive components (e.g., transmission housings, engine parts) – Appliance parts – Industrial equipment components | – Suitable for a wide range of automotive and industrial components – Balances precision and size, providing versatility in production |

| Large Structural Components | 800-2000 | Above 600 | 900 tons, 1250 tons, 1650 tons, 2000 tons | – Large automotive parts (e.g., engine blocks, chassis components) – Aerospace components – Large industrial machinery parts | – Capable of handling large, complex parts with high strength requirements – Supports production of large-scale components for heavy industries |

No. | Equipments | Brand | Locking Force(Ton) |

|---|---|---|---|

| 1 | Aluminum Alloy Die-casting Machine | YIZUMI | 2000T |

| 2 | Aluminum/Magnesium Alloy Die-casting Machine | YIZUMI | 1650T |

| 3 | Aluminum/Magnesium Alloy Die-casting Machine | YIZUMI | 1250T |

| 4 | Aluminum Alloy Die-casting Machine | YIZUMI | 900T |

| 5 | Aluminum/Magnesium Alloy Die-casting Machine | YIZUMI | 800T |

| 6 | Aluminum Alloy Die-casting Machine | LK Machinery | 630T |

| 7 | Aluminum Alloy Die-casting Machine | LK Machinery | 580T |

| 8 | Aluminum Alloy Die-casting Machine | YIZUMI | 430T/500T |

| 9 | Aluminum/Magnesium Alloy Die-casting Machine | YIZUMI | 400T/300T/180T |

| 10 | Aluminum/Magnesium Alloy Die-casting Machine | LK Machinery | 500T/400T/200T/88T |

| 11 | Zinc Alloy Die-casting Machine | YIZUMI | 88T/160T/280T |

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

Die casting is a precision manufacturing process used to produce complex metal parts with high accuracy and excellent surface finishes. It is widely employed across industries such as automotive, aerospace, electronics, and medical devices.

At Gree-Ge, we provide top-tier die casting services, offering instant quotes, fast lead times, and high-quality results that meet the most stringent industry standards.

Die casting provides exceptional dimensional accuracy, ensuring that each part maintains consistent specifications throughout the production run. This repeatability is crucial for industries that require precise tolerances, such as aerospace, medical, and automotive sectors. Once the die mold is created, thousands or even millions of identical parts can be produced efficiently with minimal additional costs per unit. This makes die casting an economical choice for high-volume manufacturing compared to other fabrication methods.

Die-cast parts exhibit superior strength-to-weight ratios, especially when using aluminum, magnesium, and zinc alloys. These metals offer a balance of durability and lightweight properties, making them ideal for structural applications requiring both resilience and reduced weight.

The die casting process inherently produces components with a high-quality surface finish. With minimal additional post-processing, die-cast parts can be used as-is or enhanced through secondary finishing treatments such as anodizing, powder coating, or plating.

Most die-cast parts come out of the mold with precise dimensions and near-net shape, reducing the need for extensive machining. This saves time, reduces material waste, and lowers overall production costs while ensuring parts meet the required specifications with minimal adjustments.

At Gree-Ge, we offer various types of die casting to suit your specific requirements. Each method has distinct advantages, making them suitable for different applications.

High-pressure die casting is the most commonly used method for producing thin-walled, high-volume metal components. It is particularly effective for aluminum, magnesium, and zinc parts that require excellent surface finishes and precise tolerances. The process involves injecting molten metal into a mold cavity under high pressure, ensuring rapid solidification and minimal defects.

This method is ideal for industries requiring lightweight, durable, and high-precision parts such as automotive, electronics, and consumer products.

Low-pressure die casting is primarily used for producing larger and structurally sound components. It is particularly beneficial for aluminum and magnesium parts that require intricate details and high strength. In this process, molten metal is forced into the mold using low pressure, allowing for a more controlled filling process that reduces turbulence and minimizes porosity. LPDC is widely used in the aerospace and automotive industries for components that demand superior metallurgical properties and durability.

Gravity die casting, also known as permanent mold casting, relies on gravity rather than pressure to fill the mold with molten metal. This process is suitable for aluminum, magnesium, and copper-based alloys and is known for producing dense, strong parts with excellent mechanical properties.

The use of reusable molds ensures consistent quality and cost efficiency over high production runs. Gravity die casting is commonly used for industrial, automotive, and aerospace applications where high structural integrity is essential.

Vacuum die casting is an advanced process designed to reduce porosity and gas entrapment, leading to improved mechanical properties and enhanced strength. This method is particularly beneficial for high-performance applications in the automotive and aerospace industries, where component reliability is crucial.

The process involves removing air from the mold cavity before injecting molten metal, resulting in parts with superior density and minimal internal defects. Vacuum die casting is ideal for producing high-strength aluminum and magnesium components with demanding quality requirements.

Squeeze die casting combines elements of forging and die casting to produce parts with exceptional mechanical strength and minimal porosity. In this process, molten metal is injected into the die and then subjected to additional pressure during solidification, ensuring high-density parts with superior durability.

This method is widely used in structural applications where strength and reliability are paramount, such as aerospace, automotive, and heavy machinery components.

Gree-Ge offers a variety of metals for die casting, each with unique characteristics suited for different applications.

Aluminum alloys are lightweight yet strong with excellent corrosion resistance, making them a preferred choice for automotive, aerospace, and consumer electronics. Common alloys used in die casting include A360, A380, A383, and A413, each offering varying levels of strength, heat resistance, and machinability.

Zinc alloys are known for their high strength, impact resistance, and excellent castability. They are ideal for high-precision, thin-walled components that require fine detail and complex geometries. Popular zinc alloys include Zamak 3, Zamak 5, and ZA-8, which are widely used in hardware, electrical, and consumer product applications.

Magnesium alloys are the lightest structural metals available, offering a unique combination of strength and reduced weight. These alloys are frequently used in aerospace, electronics, and automotive applications where weight reduction is critical. The most commonly used magnesium alloy for die casting is AZ91D, known for its corrosion resistance and excellent machinability.

Copper-based alloys, including brass and bronze, provide excellent electrical conductivity, corrosion resistance, and wear resistance. These materials are commonly used in electrical connectors, marine applications, and industrial components that require high durability and longevity. Popular copper-based alloys include C83600 and C85700.

Gree-Ge provides multiple finishing options to enhance the appearance, durability, and functionality of die-cast parts.

Our as-cast finish provides a smooth surface without additional processing, making it suitable for many applications.

For enhanced durability, powder coating offers a corrosion-resistant protective layer in various colors. Anodizing is commonly applied to aluminum parts to improve corrosion resistance and aesthetics.

Electroplating options, such as zinc, copper, nickel, and chrome, add a decorative and protective metallic layer. For custom aesthetics, painting can be applied in a wide range of colors. Shot blasting improves surface texture by removing minor imperfections, while polishing and buffing create a refined, glossy finish.

What is the lead time for die-cast parts?

Standard lead time is 10–15 business days, depending on part complexity and volume.

What materials are best for die casting?

Aluminum, zinc, and magnesium are the most commonly used materials due to their strength, lightweight properties, and corrosion resistance.

What are the size limitations for die casting?

Parts can range from small components under an inch to larger parts up to 24” x 24” x 12” depending on the alloy and casting method.

Does die casting allow for custom finishing options?

Yes, Gree-Ge offers powder coating, anodizing, electroplating, and more to enhance durability and appearance.

How do I get a quote for die-cast parts?

Simply upload your CAD file to our platform for an instant quote with pricing and lead time.