Introduction

In the dynamic world of precision manufacturing, choosing the right machining process is crucial for achieving optimal results. CNC Turning and CNC Machining are two popular techniques, each with its own set of advantages and applications. In this blog post, we’ll delve into the differences between CNC Turning and CNC Machining, helping you make an informed decision for your specific needs.

Understanding CNC Turning and CNC Machining:

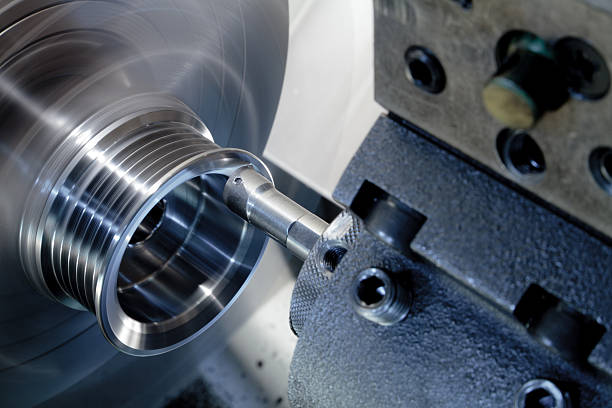

CNC Turning is a subtractive manufacturing process that involves rotating a workpiece while a cutting tool removes material to create a cylindrical shape. This technique is highly effective for producing components like shafts, pins, and bushings. The precision and speed of CNC Turning make it suitable for high-volume production runs.

CNC TURNING

- CNC Machining:

CNC Machining, on the other hand, is a broader term encompassing various processes like milling, drilling, and turning. It provides versatility in producing intricate parts with complex geometries. CNC Machining is ideal for prototypes, low-volume production, and creating components with diverse shapes and sizes.

Comparing Key Factors:

1. Material Compatibility:

CNC Turning is particularly well-suited for materials like metal, plastic, and wood, producing excellent results for cylindrical components. CNC Machining, with its broader range of processes, is suitable for a wider variety of materials, including those with complex structures.

2. Geometric Complexity:

If your project involves components with intricate shapes or multiple features, CNC Machining may be the better choice. It allows for 3D milling and other processes that cater to a more diverse range of part geometries. CNC Turning excels in producing cylindrical or conical shapes but may face limitations with complex structures.

3. Production Volume:

For high-volume production of cylindrical parts, CNC Turning is often more efficient and cost-effective. Its continuous rotation of the workpiece streamlines the manufacturing process. On the other hand, CNC Machining offers flexibility for low-volume production runs and prototyping, making it an excellent choice for customization.

4. Surface Finish:

CNC Turning tends to provide a superior surface finish for cylindrical parts due to its specialized nature. CNC Machining can achieve excellent finishes as well but may require additional processes, such as polishing or grinding, depending on the part’s complexity.

5. Speed and Efficiency:

CNC Turning’s continuous rotation allows for faster production times, making it the preferred choice for mass production. CNC Machining offers versatility but may have longer cycle times, especially when dealing with complex geometries.

Conclusion:

In conclusion, both CNC Turning and CNC Machining have their merits, and the ideal choice depends on the specific requirements of your project. For high-volume production of cylindrical components with excellent surface finish, CNC Turning is a top contender. On the other hand, if your project involves diverse materials, complex geometries, or low-volume runs, CNC Machining provides the versatility needed to meet these challenges.

Making the right decision between CNC Turning and CNC Machining involves carefully assessing your project’s specifications, volume requirements, and desired outcomes. Ultimately, both techniques contribute significantly to the precision manufacturing landscape, offering solutions tailored to different needs in the industry. Contact Gree-ge for your needs now!