CNC Routing is compatible with wood, plastics, acrylic, aluminum, composites, foam, and more.

Looking for high-precision cut parts with smooth finishes? Gree-Ge is here to help with CNC routing services on both intricate designs and complex geometries. Upload your design today and you will receive an instant quote!

Gree-Ge offers CNC routing services for plastics, composite and even non metals. Whether you’re in the signage, furniture, aerospace, or custom fabrication, our state of the art equipment guarantees clean cuts with intricate details. You can rely on Gree-Ge for prototypes and panels like with any other custom fabrication high-quality company. Custom orders in bulk are no problem as well.

CNC Routing is much more advanced than traditional cutting which relied on manual labor. The process starts with a computer controlled tool that initiates the cutting. As the tool begins carving a component, it removes a defined volume of material, forming grooves or holes. Once the portion is cut out, precise carving shapes is done ensuring every side has accurate smooth edges while the detailing becomes intricate. It is widely known for creating custom parts or pieces that are hard to cut manually.

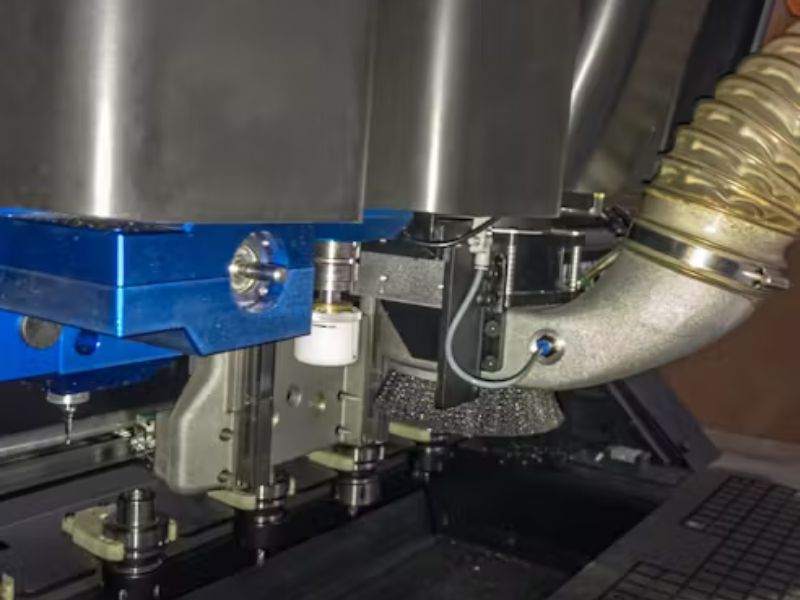

Here are our CNC Routing parts made by our modern equipment that is perfect for delivering ultra-precise cuts with intricate detailing for diverse industries.

Gree-Ge offers plastic, metal, and materials for CNC Routing as well as various options for post processing to increase surface quality, durability, and functionalities.

Foam

The fastest option, leaving parts with visible tool marks and potentially sharp edges or burrs, which can be removed upon request. Surface roughness is approximately 125 µin Ra.

Media-blasted, typically with glass beads, to create a smooth, matte finish.

Type II: Provides corrosion resistance and is available in various colors, including clear, black, red, and gold. Commonly used for aluminum.

Type III: A thicker, harder layer offering enhanced wear and corrosion resistance.

A durable coating where powdered paint is applied and cured in an oven, forming a strong, wear- and corrosion-resistant finish. Available in a wide range of colors.

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

A cutting-edge machining operation known as CNC Routing shape cuts and engravings multiple materials using exceptional precision. Gree-Ge operates exclusively to provide high-quality custom CNC routing parts which serve industries including woodworking and aerospace among others. The precision and efficient design of our CNC routers enables them to execute prototyping and large-scale manufacturing tasks with great accuracy and repeatability and efficiency.

Modern CNC (Computer Numerical Control) Routing systems automate the process of creating detailed workpieces through automated tool control which operates on diverse materials. CNC Routing delivers precise and regular outcomes which makes companies choose it over manual routing operations for producing detailed high-quality components.

Our CNC routers maintain precise accuracy levels to cut parts without inconsistencies which removes operator mistakes from the process.

CNC Routing allows users to process wood and plastics along with acrylics alongside aluminum and composite materials and additional materials in its wide range of capabilities.

The automated routing process decreases material waste while it accelerates production thus it represents an economical choice for manufacturers of every production scale.

Programmed through sophisticated algorithms CNC Routing produces advanced detailed patterns together with customized shaped designs along with engraved details suitable for artistic and functional applications.

Through CNC Routing manufacturers achieve fast production times combined with excellent product quality for their prototyping as well as their full manufacturing requirements.

This programming technology finds extensive use in the woodworking sector because it enables the creation of precise decorative panels and customized furniture and cabinetry along with intricate designs.

CNC routers excel at generating professional signs beside engraving and cutting wood aluminum and acrylic sheets to make decorative and logo products.

CNC Routing produces precise components along with panels and lightweight composite parts that find their applications in aerospace and automotive industries.

CNC routers offer industrial value by creating accurate dimensional shapes and drilled holes along with precise edge cutting for plastic and composite materials used in consumer and industrial products.

CNC Routing enables designers and architects to produce precise and complex decorative architectural elements including custom wall features.

Our company offers precise CNC Routing solutions for all your precision requirements. Contact our team right now to get project assessment and pricing.

What materials can be processed with CNC Routing?

CNC Routing is compatible with wood, plastics, acrylic, aluminum, composites, foam, and more.

How accurate is CNC Routing?

The precision level of our CNC routers reaches ±0.1mm tolerance based on design complexity and material type.

Can CNC Routing handle custom and complex designs?

Yes, CNC Routing is ideal for intricate patterns, custom engravings, and unique shapes with high repeatability.

How does CNC Routing compare to laser cutting?

CNC Routing is better for thicker materials and produces smoother edges, whereas laser cutting is preferred for ultra-fine details and thin materials.

What is the lead time for CNC Routing projects?

Turnaround times vary depending on project complexity, but we offer rapid production to meet tight deadlines.