Prototype Molding focuses on early-stage testing, while Bridge Molding supports short-run production before finalizing high-volume molds.

Need an affordable and efficient option for low-volume production? Gree-Ge offers Bridge Molding services, providing high-quality parts in the transitional stage before full-scale production. Upload your design today and receive an instant quote!

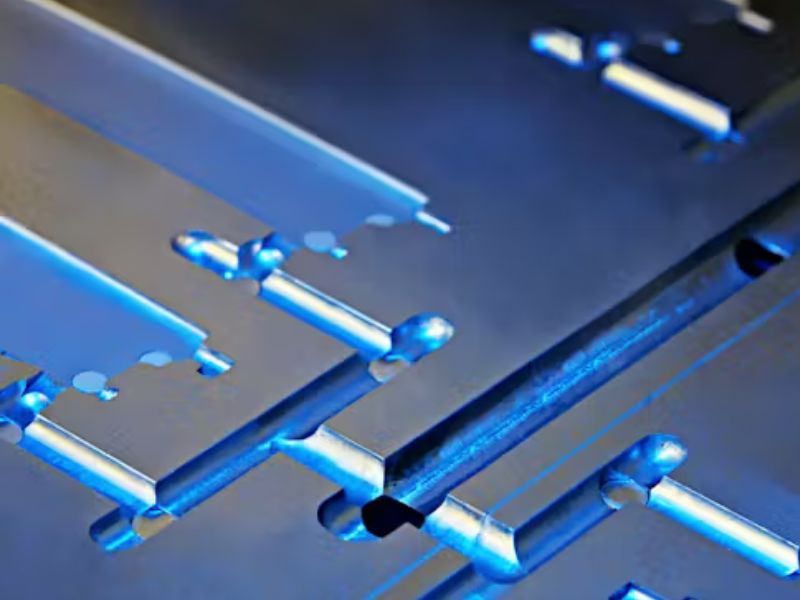

Gree-Ge offers Bridge Molding services for low-to medium-volume production runs, providing a cost-effective way to bridge the gap between prototyping and full-scale manufacturing. Our short lead times, high-quality molds, and production-grade materials ensure that your parts meet functional and aesthetic requirements for a variety of industries, including automotive, medical, and consumer electronics.

Bridge Molding is a transition phase in manufacturing, where low-volume, production-quality molds are used to create parts before scaling up to more expensive, high-volume molds. This process is ideal for situations where a product is in it’s early stages of market introduction, requiring low-cost, high-quality production parts for testing, marketing, or small-volume sales.

Explore Bridge Molding services by Gree-Ge, ideal for producing low to medium-volume parts before committing to full-scale production. Our bridge molds offer a cost-effective solution for quick, high-quality parts during the transition phase.

Our Bridge Molding materials offer a wide range of options, are certified, and environmentally friendly, providing premium solutions for your products. Contact us now to learn more!

The part is produced directly from the mold with no additional finishing, showing the natural texture from the injection molding process.

A smooth, glossy finish is applied to the molded part, typically using abrasive tools to achieve a high-quality, refined surface.

Texture is applied to the mold cavity to create matte or patterned finishes, such as stippling or grain textures.

Creates a uniform matte or satin finish by bead blasting the part with fine abrasive media, improving texture and removing surface imperfections.

Parts are placed in a vibratory finishing machine with abrasive media to smooth the surface, remove any flash, and achieve a consistent finish across the part’s surface.

Full range of manufacturing services meet diverse project requirements and provide custom parts with unmatched quality and efficiency.

Experience precision CNC machining with Gree-Ge. From intricate prototypes to large-scale production, we’re ready to bring your ideas to reality. Contact us today to discuss your project needs!

Through Bridge Molding manufacturing, companies can produce products efficiently while spending less money until they begin complete manufacturing operations. This process delivers quick deliveries of high-quality parts at an economical rate compared to permanent tooling costs.

Through the Bridge Molding services, Gree-Ge provides dependable solutions which manufacture precise requirements-based durable parts to customers. We support businesses to become more flexible while launching new products swiftly with reduced operational risks.

Economical: The initial financial expenditure required for tooling becomes cheaper through the use of bridge molding when opposed to using production molds.

Faster Time-to-Market: The manufacturing process becomes faster because the production of parts occurs quickly during the preparation phase for large-volume molds.

Design Validation: The design validation process enables product designers to conduct tests which help improve product designs ahead of mass production.

Scalability: Provides a seamless transition from prototype to full-scale manufacturing.

Flexible Production Runs: The system offers adjustable production volume which adjusts according to market demand changes.

The bridge molding system maintains a specific method to deliver both efficiency and reliability throughout its operations.

Some of the significant reasons to prefer our Bridge Molding services are:

Gree-Ge produces bridge molds through precision manufacturing with high-quality materials which fulfill all required industry regulations.

Our company supplies thermoplastics along with engineering-grade plastics and elastomers that serve different industrial applications.

Rapid manufacturing takes place with superior quality standards through our optimized processes backed by cutting-edge manufacturing tools.

We allow our clients to achieve flexible production capabilities in particular design specifications along with limited batch manufacturing and design optimization cycles.

The manufacturing solutions at Gree-Ge collaborate perfectly with Bridge Molding to provide our customers complete solutions. Our company provides comprehensive services starting from short-run production up to full-scale manufacturing as well as post-processing which covers an entire production cycle.

We provide CNC machining through our services which flourishes the design process between Bridge Molding and finally finalizing the injection mold operation.

After successful completion of Bridge Molding we guide our customers to move toward large-scale production through durable and affordable mold manufacturing.

Bridge Molding follows rapid prototyping through several options including 3D printing and prototype molding to validate product designs.

The facility performs secondary operations which include painting along with pad printing and ultrasonic welding to get products ready for market release.

So, without any delay, Contact Gree-Ge today and get to know more about our Bridge Molding services. Now it’s time take your product from concept to full-scale production with confidence!

Prototype Molding focuses on early-stage testing, while Bridge Molding supports short-run production before finalizing high-volume molds.

Yes, it provides an affordable solution for low-volume production without the high cost of full-scale molds.

Absolutely. It produces fully functional parts that can be tested in real-world applications before mass production.

Turnaround times vary but typically range from a few weeks to a couple of months, depending on complexity and order volume.

Gree-Ge offers ABS, polycarbonate, nylon, PEEK, and other engineering-grade plastics based on performance requirements